鈑金尖角倒鈍

鈑金尖角倒鈍

![]()

![]()

![]()

套用圓角或倒角來在現有的鈑金零件上鈍化尖角。選擇尖角邊線或頂點,然後指定尖角倒鈍類型與距離。建議在完成鈑金模型的所有凸緣與接合後再使用這個特徵。

在鈑金設計的最後階段會牽涉到工作之一ˋ是鈍化尖角以避免傷害與障礙。Onshape 鈑金中的尖角倒鈍特徵藉由將圓角或倒角加入到任何所選邊線上來達成此任務。

請將「尖角倒鈍」保留為鈑金零件最後的特徵。在套用「尖角倒鈍」特徵之後,即無法修改「接合類型」與「樣式」。

「尖角倒鈍」可套用到鈑金零件的任何轉角上,即使是用「彎折止裂」切除建立的轉角。

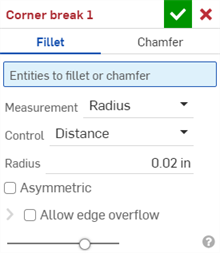

開始一個新的「尖角倒鈍」特徵。選擇「圓角」或「倒角」分頁,然後選擇鈑金零件的一或多個轉角邊或頂點。可以從成形或展平的狀態中選擇轉角。

對於「圓角」,請為「測量」選擇「半徑」或「寬度」。此外,請將「控制項」設定為「距離」、「圓錐」或「曲率」。

設定半徑或寬度值來決定圓角的尺寸。對於基於圓錐的圓角,請設定「Rho」值。對於基於曲率的圓角,請設定「量值」。

對於由兩個半徑混合組成的圓角,請核取「不對稱」,然後輸入「第二半徑」。需要時請切換「反轉不對稱」的箭頭。

「距離」與「圓錐」都有「允許邊線溢出」的選項。核取這個選項來允許圓角特徵修改由圓角建立的面邊線,進而產生平滑連續性的曲面。當您不核取這個選項時,Onshape 會保留在圓角面上的邊線。

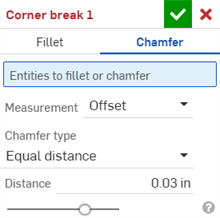

對於「倒角」,請為「測量」設定「偏移」或「相切」,然後選擇一個「倒角類型」。「同等距離」會將倒角從邊線向兩個方向延伸相同的距離。「兩個距離」會根據每個輸入的距離值延伸倒角。「距離和角度」 以指定的距離在一個方向延伸倒角,在另一個方向以指定的角度延伸倒角。使用後面兩個選項時,您可以切換「相反方向」箭頭來切換邊。

若要在鈑金模型上建立圓化的尖角倒鈍:

- 在 Part Studio 內現有的鈑金模型中,按一下尖角倒鈍 (

)。

)。

- 為尖角倒鈍類型選擇圓角。

- 在圖形區域中選擇鈑金模型上的一個轉角邊或頂點。也可以在鈑金模型與展開視圖的展開視圖部分選擇轉角邊或頂點。

- 選擇測量的類型,可以是:

- 半徑 - 指定圓角的半徑測量值。

- 寬度 - 指定圓角兩端間的距離 (一個固定寬度)。

- 選擇一個「控制項」類型:

- 距離 - 圓角有圓形邊線,並已輸入了半徑ˋ值。在建立新圓角時,Onshape 會記住這個值。

- 圓錐 - 圓角有錐形邊線,並有您輸入的半徑。可選擇性使用 Rho 值來定義圓角的樣式:

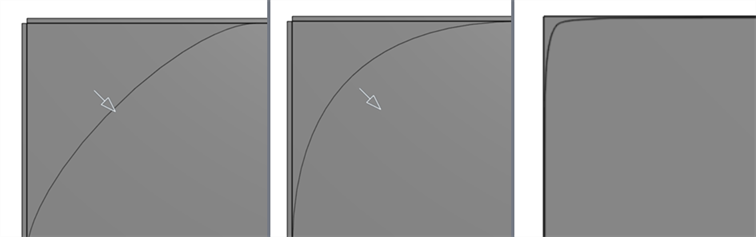

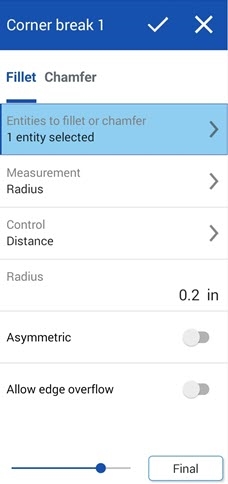

Rho 值:0.25 (左圖;橢圓曲線);0.5 (ˋ中間圖;拋物線);0.999 (右圖;雙曲線 - 放大)

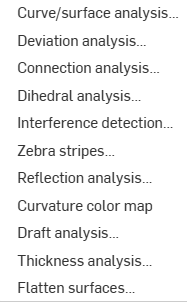

- 曲率 - 圓角與鄰近邊線的曲率配合,並有您輸入的半徑值。可選擇性使用介於 0 到 .999 之間的量值來調整相切。開啟斑馬條紋 (從「顯示分析工具」功能表中) 來更清楚地查看相切:

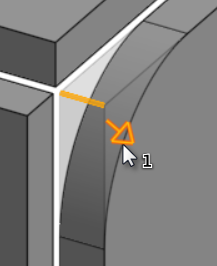

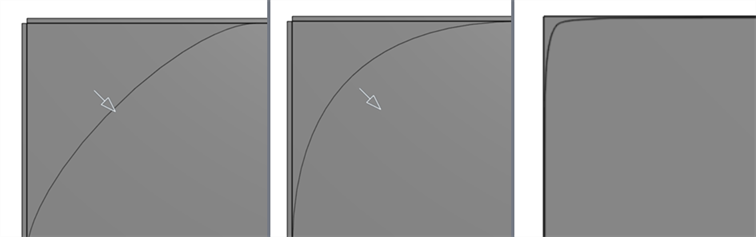

當輸入半徑值時,您也可以使用拖曳操控器 (在下圖中以箭頭表示) 來視覺呈現圓角並達到所要的預估值:

Onshape 會記住對「測量類型」的選取項目與ˊ值,在後續的操作中打開對話方塊時即會有最後選取的選項。

- 核取不對稱,然後輸入第二半徑來在圓角邊線的另一端有不同的圓角邊線半徑值。按一下反轉不對稱箭頭來使用圓角的另一端做為第二 (不對稱) 圓角邊線。

- 根據預設,允許邊線溢出是停用的。核取來在需要的情況下允許從圓角曲面「刪除」相切邊線。由預設產生的邊線會嚴格限制沿著圓角邊線的圓角方向。當啟用允許邊線溢出時,圓角可以修改由圓角所產生面的邊線,以產生平滑連續性的曲面。當停用這個選項時,系統會保留已圓角面上的邊線,進而建立較自由流動的零件。

按一下「允許邊線溢出」下拉清單來開啟您可於其中選擇要保留邊線的欄位。

- 按一下核取記號 (

) 來接受新的「尖角倒鈍」特徵。

) 來接受新的「尖角倒鈍」特徵。

若要在鈑金模型上建立倒角的尖角倒鈍:

- 在 Part Studio 內現有的鈑金模型中,按一下尖角倒鈍 (

)。

)。

- 為尖角倒鈍類型選擇倒角。

- 在圖形區域中選擇鈑金模型上的一個轉角邊或頂點。也可以在鈑金模型與展開視圖的展開視圖部分選擇轉角邊或頂點。

- 選擇測量的類型,可以是:

- 偏移 - 設定在「距離」欄位中輸入從開始邊線到倒角的距離。這個選項是取決於邊線的;計算是從第一個選取項目開始然後連續進行。

- 相切 - 設定在「距離」欄位中輸入從兩個相鄰面相切交會到倒角的距離。這個選項不是取決於邊線的。

- 選擇一個「倒角類型」:

- 同等距離 - 倒角會從邊線往兩個方線延伸同等的距離。

- 兩個距離 - 倒角會在每個方向上延伸不同的距離。

- 距離和角度 - 倒角會在一個方向上延伸指定的距離,在另一個方向上延伸指定的角度。

Onshape 會記住對「倒角類型」的選擇,在後續的操作中打開對話方塊時即會是上次所做的選擇。

- 輸入倒角的距離。Onshape 對角度的預設是 45 度,但會記住上次為同等距離和距離及角度倒角輸入的值。

- 如果您選擇兩個距離或距離和角度,按一下箭頭按鈕來反轉所有邊線的方向,或在方向取代欄位中指定要反轉的個別邊線。

- 按一下核取記號 (

) 來接受新的「尖角倒鈍」特徵。

) 來接受新的「尖角倒鈍」特徵。

-

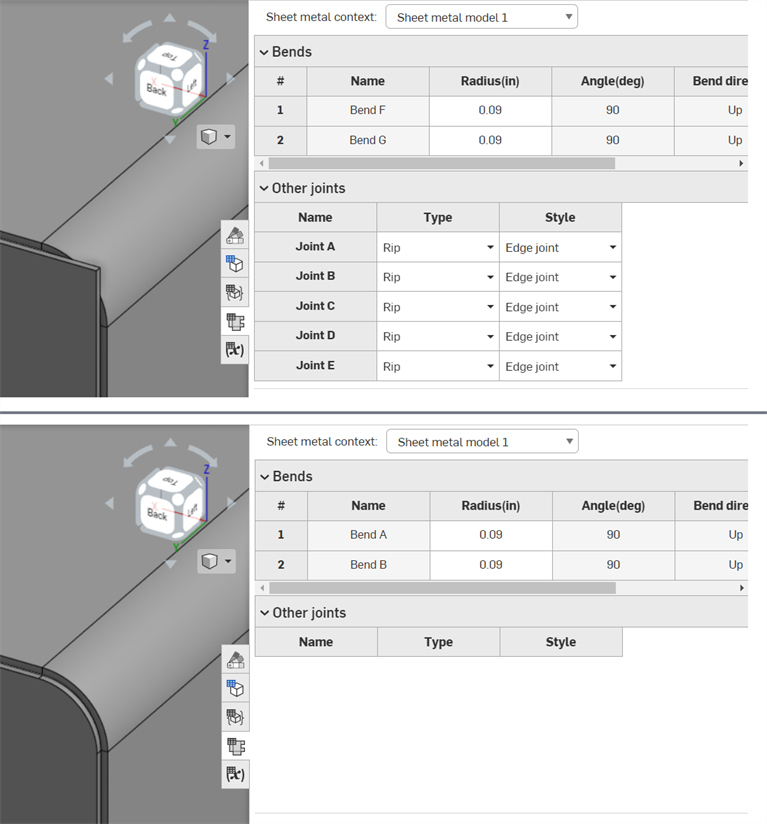

在套用「尖角倒鈍」特徵之後,將無法再編輯鈑金模型表格與展開視圖中所有模型的接合類型 (裂口或彎折) 與樣式 (邊線接合或對接)。建議您在完成鈑金模型凸緣與接合的所有編輯之後再套用「尖角倒鈍」特徵。

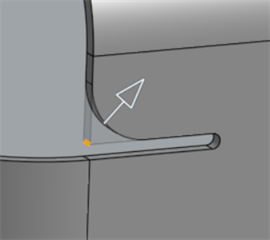

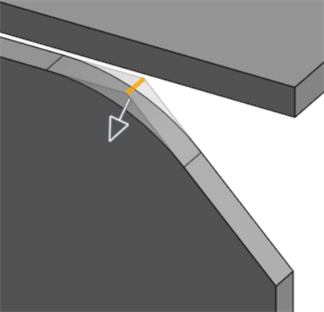

套用「尖角倒鈍」特徵之前 (上圖);套用「尖角倒鈍」特徵之後 (下圖)

-

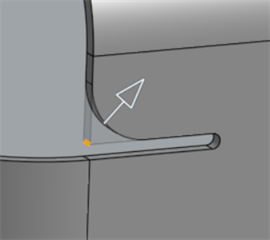

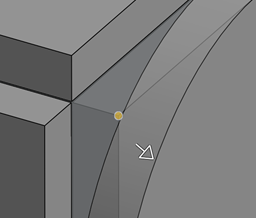

您可以使用「尖角倒鈍」來將圓角或倒角套用到彎折止裂的邊線和頂點上 (除了轉角之外):

-

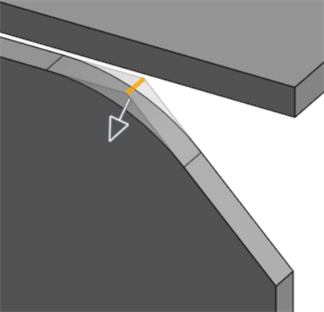

您不能使用單一「尖角倒鈍」特徵來將多個圓角、倒角或兩者的合併加入到轉角上。建立額外的「尖角倒鈍」特徵來將額外的圓角或倒角加入到先前已存在「尖角倒鈍」特徵的頂點或邊線上:

使用第二個「尖角倒鈍」特徵來將圓角套用到已倒角的邊線上

當鈑金模型啟用時 (在建立或編輯鈑金的過程中),其他可用的工具包括:

-

凸緣 - 為每條所選的邊線建立牆面,使用彎折來連接所選的邊線。

凸緣 - 為每條所選的邊線建立牆面,使用彎折來連接所選的邊線。 -

摺邊 - 在現有的鈑金零件上為所選取的邊線/面建立摺邊。

摺邊 - 在現有的鈑金零件上為所選取的邊線/面建立摺邊。 -

薄板頁 - 將一個薄板頁加入至鈑金凸緣中。

薄板頁 - 將一個薄板頁加入至鈑金凸緣中。 -

Bend - Bend a sheet metal model along a reference line, with additional bend control options.

Bend - Bend a sheet metal model along a reference line, with additional bend control options. -

Form - Create form features on existing sheet metal models. Forms can be selected from the current document, other documents, or a predefined library of sheet metal forms.

Form - Create form features on existing sheet metal models. Forms can be selected from the current document, other documents, or a predefined library of sheet metal forms. -

Loft - Create sheet metal models that connect two profiles.

Loft - Create sheet metal models that connect two profiles. -

製作接合 - 將兩個牆面的相交處轉換為一個接合特徵,可以是一個彎折 (以圓柱幾何接合牆面),或是一個裂口 (兩個牆之間的小間隙)。

製作接合 - 將兩個牆面的相交處轉換為一個接合特徵,可以是一個彎折 (以圓柱幾何接合牆面),或是一個裂口 (兩個牆之間的小間隙)。 -

轉角 - 修改轉角類型與止裂比例。

轉角 - 修改轉角類型與止裂比例。 -

彎折止裂 - 修改彎折止裂 (在彎折結束與自由邊線交會處做出的小切除)、深度與止裂寬度。

彎折止裂 - 修改彎折止裂 (在彎折結束與自由邊線交會處做出的小切除)、深度與止裂寬度。 -

Modify joint - Make changes to an existing joint, such as converting a bend to a rip. Currently available through the flat view table.

Modify joint - Make changes to an existing joint, such as converting a bend to a rip. Currently available through the flat view table. -

Corner break - Break the corner on existing sheet metal parts by applying a fillet or chamfer. Select a corner edge or vertex and specify corner break type and distance. It is recommended to use this feature after all flanges and joints of the Sheet metal model are finalized.

Corner break - Break the corner on existing sheet metal parts by applying a fillet or chamfer. Select a corner edge or vertex and specify corner break type and distance. It is recommended to use this feature after all flanges and joints of the Sheet metal model are finalized. -

Sheet metal table and flat view - Open and close the Rip/Bend tables and the visualization of the sheet metal model flat pattern. Use this table to convert rips to bends and vice versa.

Sheet metal table and flat view - Open and close the Rip/Bend tables and the visualization of the sheet metal model flat pattern. Use this table to convert rips to bends and vice versa. -

完成鈑金模型 - 關閉 (停用) 鈑金模型;建立特徵清單中的特徵。

完成鈑金模型 - 關閉 (停用) 鈑金模型;建立特徵清單中的特徵。

若要在鈑金模型上建立圓化的尖角倒鈍:

- 在 Part Studio 內的現有鈑金模型中,輕觸尖角倒鈍 (

)。

)。

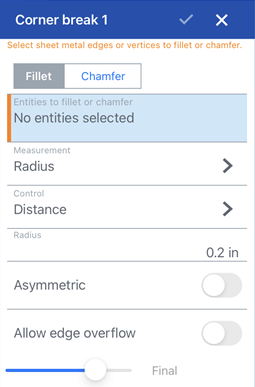

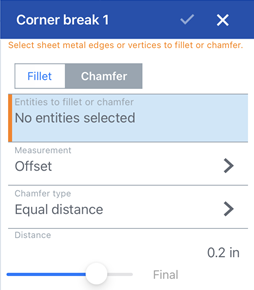

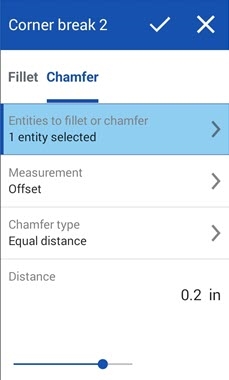

尖角倒鈍:iOS 中的「圓角」對話方塊 (上方第一個圖片) 與 Android 中的「圓角」對話方塊 (上方第二個圖片)

- 為尖角倒鈍類型選擇輕觸圓角。

- 在圖形區域中選擇鈑金模型上的一個轉角邊或頂點。

- 選擇測量的類型,可以是:

- 半徑 - 指定圓角的半徑測量值。

- 寬度 - 指定圓角兩端間的距離 (一個固定寬度)。

- Select a Control type:

- Distance - Fillet has a circular edge with the radius value entered. Onshape remembers this value when creating new fillets.

- Conic - Fillet has a conical edge with the radius value you enter and optionally a Rho value to define the style of the fillet:

Rho values: 0.25 (left; elliptical curve); 0.5 (middle; parabolic curve); 0.999 (right; hyperbolic curve - zoomed in)

- Curvature - Fillet matches the curvature of the surrounding edges with a radius value you enter and optionally a Magnitude value between 0 and .999 to adjust the tangency.

當輸入半徑值時,您也可以使用拖曳操控器 (在下圖中以箭頭表示) 來視覺呈現圓角並達到所要的預估值:

- 切換開啟不對稱,然後輸入第二半徑來在圓角邊線的另一端有不同的圓角邊線半徑值。切換反轉不對稱箭頭來使用圓角的另一端做為第二 (不對稱) 圓角邊線。

- 根據預設,允許邊線溢出的切換是關閉的。切換開啟這個選項來在需要的情況下允許從圓角曲面「刪除」相切邊線。由預設產生的邊線會嚴格限制沿著圓角邊線的圓角方向。當啟用允許邊線溢出時,圓角可以修改由圓角所產生面的邊線,以產生平滑連續性的曲面。當切換關閉這個選項時,系統會保留已圓角面上的邊線,進而建立較自由流動的零件。

輕觸保留的邊線欄位然後在圖形區域中選擇要保留的任何邊線。

- 輕觸核取記號來接受新的「尖角倒鈍」特徵。

若要在鈑金模型上建立倒角的尖角倒鈍:

- 在 Part Studio 內的現有鈑金模型中,輕觸尖角倒鈍 (

)。

)。

尖角倒鈍:iOS 中的「倒角」對話方塊 (上方第一個圖片) 與 Android 中的「倒角」對話方塊 (上方第二個圖片)

- 為尖角倒鈍類型輕觸倒角。

- 在圖形區域中選擇鈑金模型上的一個轉角邊或頂點。

- 選擇測量的類型,可以是:

- 偏移 - 設定在「距離」欄位中輸入從開始邊線到倒角的距離。這個選項是取決於邊線的;計算是從第一個選取項目開始然後連續進行。

- 相切 - 設定在「距離」欄位中輸入從兩個相鄰面相切交會到倒角的距離。這個選項不是取決於邊線的。

- Select a Chamfer type:

- 同等距離 - 倒角會從邊線往兩個方線延伸同等的距離。

- 兩個距離 - 倒角會在每個方向上延伸不同的距離。

- 距離和角度 - 倒角會在一個方向上延伸指定的距離,在另一個方向上延伸指定的角度。

- 輸入倒角的距離。Onshape 對角度的預設是 45 度,但會記住上次為同等距離和距離及角度倒角輸入的值。

- 如果您選擇兩個距離或距離和角度,輕觸箭頭按鈕來反轉所有邊線的方向,或在方向取代欄位中指定要反轉的個別邊線。

- 輕觸核取記號來接受新的「尖角倒鈍」特徵。

-

在套用「尖角倒鈍」特徵之後,將無法再編輯鈑金模型表格與展開視圖中所有模型的接合類型 (裂口或彎折) 與樣式 (邊線接合或對接)。建議您在完成鈑金模型凸緣與接合的所有編輯之後再套用「尖角倒鈍」特徵。

-

您可以使用「尖角倒鈍」來將圓角或倒角套用到彎折止裂的邊線和頂點上 (除了轉角之外):

-

您不能使用單一「尖角倒鈍」特徵來將多個圓角、倒角或兩者的合併加入到轉角上。建立額外的「尖角倒鈍」特徵來將額外的圓角或倒角加入到先前已存在「尖角倒鈍」特徵的頂點或邊線上:

使用第二個「尖角倒鈍」特徵來將圓角套用到已倒角的邊線上

當鈑金模型啟用時 (在建立或編輯鈑金的過程中),其他可用的工具包括:

-

凸緣 - 為每條所選的邊線建立牆面,使用彎折來連接所選的邊線。

凸緣 - 為每條所選的邊線建立牆面,使用彎折來連接所選的邊線。 -

薄板頁 - 將一個薄板頁加入至鈑金凸緣中。

薄板頁 - 將一個薄板頁加入至鈑金凸緣中。 -

製作接合 - 將兩個牆面的相交處轉換為一個接合特徵,可以是一個彎折 (以圓柱幾何接合牆面),或是一個裂口 (兩個牆之間的小間隙)。

製作接合 - 將兩個牆面的相交處轉換為一個接合特徵,可以是一個彎折 (以圓柱幾何接合牆面),或是一個裂口 (兩個牆之間的小間隙)。 -

轉角 - 修改轉角類型與止裂比例。

轉角 - 修改轉角類型與止裂比例。 -

彎折止裂 - 修改彎折止裂 (在彎折結束與自由邊線交會處做出的小切除)、深度與止裂寬度。

彎折止裂 - 修改彎折止裂 (在彎折結束與自由邊線交會處做出的小切除)、深度與止裂寬度。 -

Loft - View and modify sheet metal models that connect two profiles.

Loft - View and modify sheet metal models that connect two profiles. -

Corner break - Break the corner on existing sheet metal parts by applying a fillet or chamfer. Select a corner edge or vertex and specify corner break type and distance. It is recommended to use this feature after all flanges and joints of the Sheet metal model are finalized.

Corner break - Break the corner on existing sheet metal parts by applying a fillet or chamfer. Select a corner edge or vertex and specify corner break type and distance. It is recommended to use this feature after all flanges and joints of the Sheet metal model are finalized. -

完成鈑金模型 - 關閉 (停用) 鈑金模型;建立特徵清單中的特徵。

完成鈑金模型 - 關閉 (停用) 鈑金模型;建立特徵清單中的特徵。