钣金尖角倒钝

钣金尖角倒钝

![]()

![]()

![]()

通过应用圆角或倒角来倒钝现有钣金零件的尖角。选择尖角边或顶点并指定尖角倒钝类型和距离。建议在钣金模型的所有法兰和联接点最终确定后使用此特征。

钣金设计的最后步骤之一是倒钝尖角以防止受伤和卡住。Onshape 的“钣金尖角倒钝”特征通过在任何选定的尖角添加圆角或倒角来实现这一点。

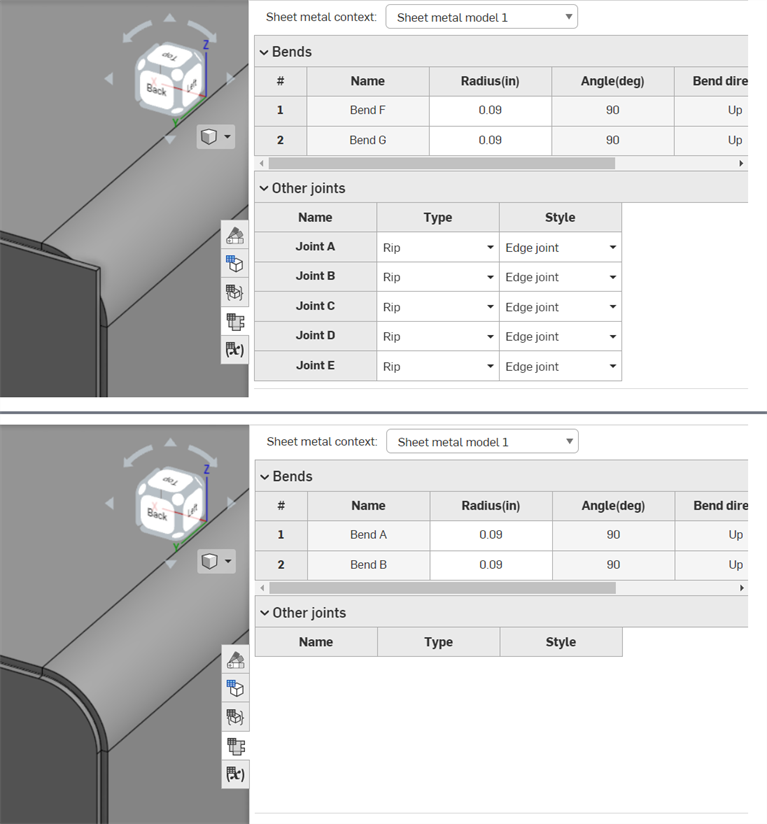

为钣金零件的最终特征预留“尖角倒钝”。一旦应用了“尖角倒钝”特征,就无法修改“联接点”类型和“样式”。

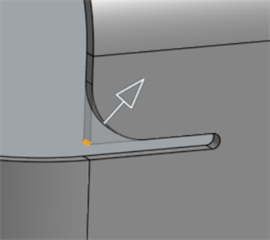

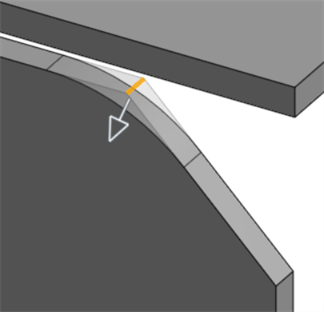

“尖角倒钝”适用于钣金零件中的任何尖角,即使是由于“折弯止裂”切口而产生的拐角。

启动新的“尖角倒钝”特征。选择“圆角”或“倒角”选项卡,然后选择钣金零件的一个或多个尖角边或顶点。可以在成型或展平状态下选择尖角。

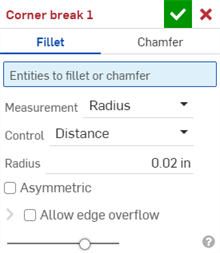

对于圆角,选择半径或宽度进行测量。此外,将圆角的“控制”选项设置为“距离”、“圆锥”或“曲率”。

设置半径或宽度值以确定圆角的尺寸。对于基于圆锥形的圆角,设置 Rho 值。对于基于曲率的圆角,设置“幅度”。

对于由两个半径混合在一起的圆角,选中“不对称”并输入第二半径。必要时切换“反转”非对称箭头。

距离和圆锥都有“允许边缘溢出”选项。选中此选项允许圆角特征修改圆角创建的面的边,从而形成光滑、连续的曲面。当您未选中此选项时,OnShape 会保留带圆角的面的边。

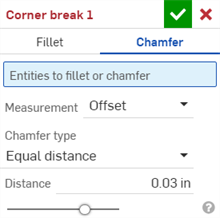

对于倒角,将测量值设置为“偏移”或“切线”。然后,选择“倒角”类型。等距离使倒角在两个方向上与边相等的距离延伸。每输入一个距离值,两个距离将使倒角延伸。距离和角度在一个方向上将倒角延伸到指定的距离,在另一个方向上延伸一个指定的角度。使用这两个选项,您可以切换相反方向箭头来切换侧面。

若要在钣金模型上创建带圆角的尖角倒钝,请执行以下操作:

- 在现有钣金模型的 Part Studio 中,单击尖角倒钝 (

)。

)。

- 尖角倒钝类型选择“圆角”。

- 在图形区域中选择钣金模型的角边或顶点。也可以在钣金模型和平面视图的平面视图部分中选择角边或顶点。

- 选择测量类型,可以是:

- 半径 - 指定圆角的半径测量值。

- 宽度 - 指定圆角两端之间的距离(恒定宽度)。

- 选择控制类型:

- 距离 - 圆角的边为圆形,且输入了半径值。创建新圆角时,Onshape 会记住这个值 。

- 圆锥 - 圆角具有圆锥边,且半径为您所输入的值,还可以选择使用 Rho 值定义圆角的样式:

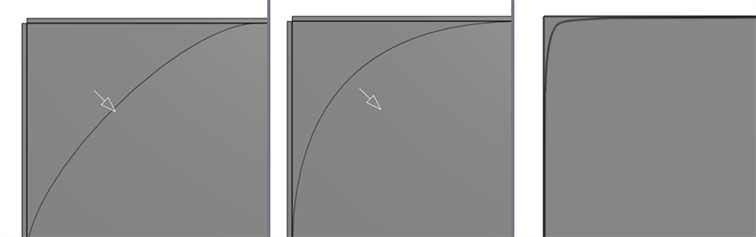

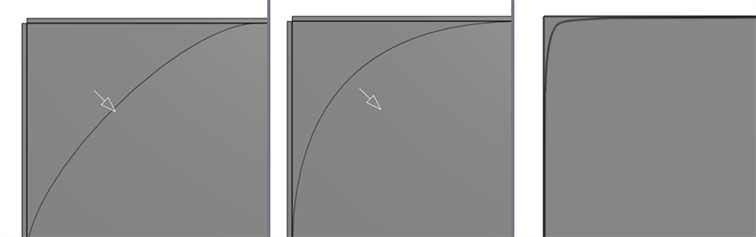

Rho 值:0.25(左;椭圆曲线):0.5(中间;抛物线曲线);0.999(右;双曲曲线 - 放大)

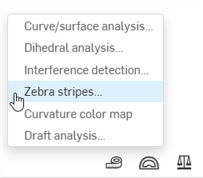

- 曲率 - 圆角将周围边的曲率与您输入的半径值相匹配,也可以将介于 0 到 .999 之间的“幅值”进行匹配以调整切线。(从“显示分析工具”菜单中)启用“斑马条纹”可以更清楚地看到切线:

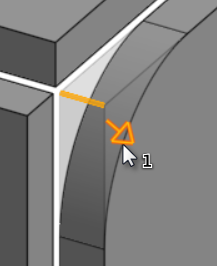

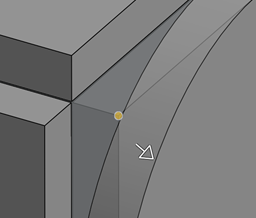

输入半径值时,您也可以使用下图中以箭头指示的拖动操纵器来可视化圆角并得到估计值:

Onshape 会记住“测量类型”和值的选择,并在后续操作中让打开的对话框中显示上次选择的选项。

- 选中“不对称”并输入第二半径,以便圆角边的一端具有不同的圆角边半径值。单击“反转不对称”箭头,将圆角的另一端作为第二(不对称)圆角边。

- 默认情况下,“允许边溢出”处于启用状态,选中即允许在必要时从圆角曲面中“删除”切线边。默认生成的边严格限制圆角沿圆角边的方向。启用“允许边溢出”后,圆角可以修改圆角在面上创建的边,以形成光滑、连续的曲面。如果未选中该选项,则圆角面的边会被保留,从而使零件更加自由流动。

单击“允许边溢出”下拉列表打开一个输入框,您可以在其中选择要保留的边。

- 单击复选标记 (

) 以接受新的“尖角倒钝”特征。

) 以接受新的“尖角倒钝”特征。

要在钣金模型上创建倒角的尖角倒钝,请执行以下操作:

- 在现有钣金模型的 Part Studio 中,单击尖角倒钝 (

)。

)。

- 尖角倒钝类型选择“倒角”。

- 在图形区域中选择钣金模型的角边或顶点。也可以在钣金模型和平面视图的平面视图部分中选择角边或顶点。

- 选择测量类型,可以是:

- 偏移 - 设置在“距离”输入框中输入的从起始边到倒角的距离。此选项依赖于边;计算从第一个选择开始,然后在链中进行 。

- 切线 - 设置在“距离”输入框中输入的从两个相邻面的切线交点到倒角的距离。此选项不依赖于边。

- 选择倒角类型:

- 相等的距离 - 倒角将在两个方向上从边延伸相等的距离。

- 两个距离 - 倒角将在每个方向上延伸不同的距离。

- 距离和角度 - 倒角将在一个方向上延伸指定距离,在另一个方向上延伸指定角度。

Onshape 会记住“倒角类型”的选择,并在后续操作中让打开的对话框中显示上次选择的选项。

- 输入倒角的“距离”。Onshape 的默认角度为 45 度,但是,会记住上次为“等距离”倒角以及“距离和角度”倒角输入的距离值。

- 如果您选择了“两个距离”或“距离和角度”,单击箭头按钮以反转所有边的方向,或在“方向替代”输入框中指定要反转的单条边。

- 单击复选标记 (

) 以接受新的“尖角倒钝”特征。

) 以接受新的“尖角倒钝”特征。

当钣金模型处于活动状态时(在创建或编辑的过程中),可使用其他工具:

-

法兰 - 为选定的每条边创建壁,通过折弯连接到选定的边。

法兰 - 为选定的每条边创建壁,通过折弯连接到选定的边。 -

卷边 - 在现有钣金零件上,为选定的每条边/每个面创建卷边。

卷边 - 在现有钣金零件上,为选定的每条边/每个面创建卷边。 -

薄片 - 向钣金法兰添加薄片。

薄片 - 向钣金法兰添加薄片。 -

折弯 - 沿参考线折弯钣金模型,并提供其他折弯控制选项。

折弯 - 沿参考线折弯钣金模型,并提供其他折弯控制选项。 -

成型 - 在现有钣金模型上创建成型特征。可以从当前文档、其他文档或预定义的钣金成型库中选择成型。

成型 - 在现有钣金模型上创建成型特征。可以从当前文档、其他文档或预定义的钣金成型库中选择成型。 -

制作接头 - 将两个壁的交点转换为接头特征,使其成为折弯(由圆柱几何图元接头的壁)或接缝(两个壁之间的小间隙)。

制作接头 - 将两个壁的交点转换为接头特征,使其成为折弯(由圆柱几何图元接头的壁)或接缝(两个壁之间的小间隙)。 -

拐角 - 修改拐角类型和止裂槽比例。

拐角 - 修改拐角类型和止裂槽比例。 -

折弯止裂槽 - 修改折弯止裂槽(折弯末端与自由边相交处的小切口)、深度和止裂槽宽度。

折弯止裂槽 - 修改折弯止裂槽(折弯末端与自由边相交处的小切口)、深度和止裂槽宽度。 -

修改接头 - 修改现有接头,例如将折弯转换为接缝。当前,可以通过展开视图表使用此功能。

修改接头 - 修改现有接头,例如将折弯转换为接缝。当前,可以通过展开视图表使用此功能。 -

尖角倒钝 - 通过应用圆角或倒角来打破现有钣金零件的尖角。选择尖角边或顶点并指定尖角倒钝类型和距离。建议在钣金模型的所有法兰和联接点最终确定后使用此特征。

尖角倒钝 - 通过应用圆角或倒角来打破现有钣金零件的尖角。选择尖角边或顶点并指定尖角倒钝类型和距离。建议在钣金模型的所有法兰和联接点最终确定后使用此特征。 -

钣金表格和展开视图 - 打开和关闭接缝/折弯表以及钣金模型展开图样的可视化。使用此表将接缝与折弯互相转换。

钣金表格和展开视图 - 打开和关闭接缝/折弯表以及钣金模型展开图样的可视化。使用此表将接缝与折弯互相转换。 -

结束钣金模型 - 关闭(取消激活)钣金模型;在特征列表中创建特征。

结束钣金模型 - 关闭(取消激活)钣金模型;在特征列表中创建特征。

若要在钣金模型上创建带圆角的尖角倒钝,请执行以下操作:

- 在已有钣金模型的 Part Studio 中,轻按尖角倒钝 (

)。

)。

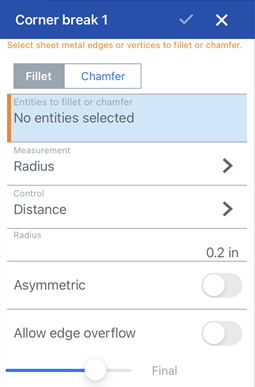

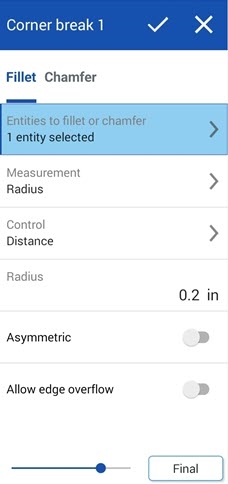

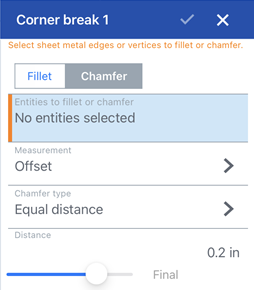

尖角倒钝:iOS(上方第一张图片)和 Android(上面第二张图片)的“圆角”对话框

- 轻按“圆角”以选择尖角倒钝类型。

- 在图形区域中选择钣金模型的尖角边或顶点。

- 选择测量类型,可以是:

- 半径 - 指定圆角的半径测量值。

- 宽度 - 指定圆角两端之间的距离(恒定宽度)。

- 选择控制类型:

- 距离 - 圆角的边为圆形,且输入了半径值。创建新圆角时,Onshape 会记住这个值 。

- 圆锥 - 圆角具有圆锥边,且半径为您所输入的值,还可以选择使用 Rho 值定义圆角的样式:

Rho values: 0.25 (left; elliptical curve); 0.5 (middle; parabolic curve); 0.999 (right; hyperbolic curve - zoomed in)

- 曲率 - 圆角将周围边的曲率与您输入的半径值相匹配,也可以将介于 0 到 .999 之间的“幅值”进行匹配以调整切线。(从“显示分析工具”菜单中)启用“斑马条纹”可以更清楚地看到切线:

输入半径值时,您也可以使用下图中以箭头指示的拖动操纵器来可视化圆角并得到估计值:

- 选中“不对称”并输入第二半径,以便圆角边的一端具有不同的圆角边半径值。单击“反转不对称”箭头,将圆角的另一端作为第二(不对称)圆角边。

- 默认情况下,“ 允许边溢出”处于关闭状态。如有必要,启用此选项可允许将相切边从圆角曲面上“删除”。默认生成的边严格限制圆角沿圆角边的方向。启用“允许边溢出”后,圆角可以修改圆角在面上创建的边,以形成光滑、连续的曲面。如果关闭该选项,则圆角面的边会被保留,从而使零件更加自由流动。

轻按要保留的边选择要在图形区域保留的边。

- 轻按复选标记以接受新的“尖角倒钝”特征。

要在钣金模型上创建倒角的尖角倒钝,请执行以下操作:

- 在已有钣金模型的 Part Studio 中,轻按尖角倒钝 (

)。

)。

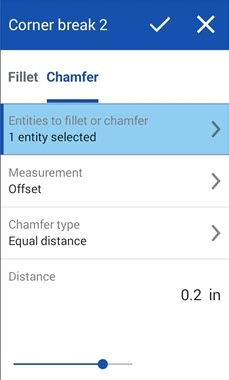

尖角倒钝:iOS(上方第一张图片)和 Android(上面第二张图片)的“倒角”对话框

- 轻按“倒角”以选择尖角倒钝类型。

- 在图形区域中选择钣金模型的尖角边或顶点。

- 选择测量类型,可以是:

- 偏移 - 设置在“距离”输入框中输入的从起始边到倒角的距离。此选项依赖于边;计算从第一个选择开始,然后在链中进行 。

- 切线 - 设置在“距离”输入框中输入的从两个相邻面的切线交点到倒角的距离。此选项不依赖于边。

- 选择倒角类型:

- 相等的距离 - 倒角将在两个方向上从边延伸相等的距离。

- 两个距离 - 倒角将在每个方向上延伸不同的距离。

- 距离和角度 - 倒角将在一个方向上延伸指定距离,在另一个方向上延伸指定角度。

- 输入倒角的“距离”。Onshape 的默认角度为 45 度,但是,会记住上次为“等距离”倒角以及“距离和角度”倒角输入的距离值。

- 如果您选择了“两个距离”或“距离和角度”,单击箭头按钮以反转所有边的方向,或在“方向替代”输入框中指定要反转的单条边。

- 轻按复选标记以接受新的“尖角倒钝”特征。

当钣金模型处于活动状态时(在创建或编辑的过程中),可使用其他工具: