Model Based Definition (MBD)

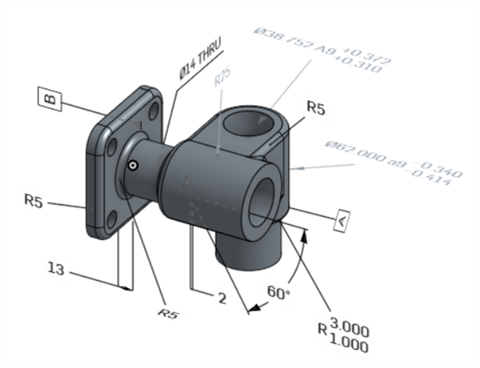

![]()

![]()

![]()

Model based definition (MBD) refers to the process of dimensioning and annotating the model in the Part Studio so the model contains all the data needed to define a product, With MBD, the model becomes the source authority that drives all engineering activities. This model may further be used downstream by suppliers and across organizations within an enterprise.

Some features of MBD:

-

Dimension and annotation metadata embedded in the model in the Part Studio.

-

Improve real-time collaboration on the model in the Part Studio.

-

Provide a single source of truth for engineers across the organization.

-

Link to downstream processes like Coordinate measuring machine (CMM) inspection

-

Replace paper drawing, for vendor-neutral archival of design and design intent.

MBD is not intended to replace Drawings. MBD is intended to capture and extend a model's Product manufacturing information (PMI) and Model-based enterprise (MBE) information for additional or alternative downstream usage.

Toleranzen definieren den zulässigen Wertebereich für eine angegebene Skizzenbemaßung oder einen Feature-Parameter, wie Extrusionstiefe, Rotierwinkel oder Bohrungsdurchmesser. Toleranzen können nicht für alle Skizzenbemaßungen oder Feature-Parameter verwendet werden.

Toleranzen sind in FeatureScript verfügbar und können in benutzerdefinierten Features verwendet werden. Weitere Informationen finden Sie unter Benutzerdefinierte Features und in der Dokumentation von FeatureScript.

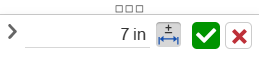

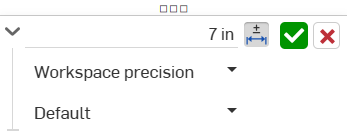

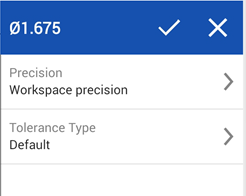

Das Dialogfenster „Bemaßungskontext“ wird verwendet, um Skizzen- und Feature-Bemaßungen zu bearbeiten und Toleranzen hinzuzufügen. Durch Doppelklicken auf eine Bemaßung in einer Skizze oder auf eine MBD-Bemaßung im Grafikbereich wird dieses Dialogfenster geöffnet. Siehe MBD-Bemaßungen bearbeiten.

-

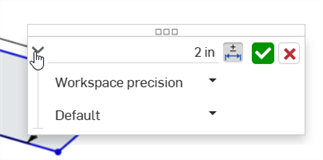

Klicken Sie auf das Toleranzsymbol (

), um der Bemaßung eine Toleranz hinzuzufügen.

), um der Bemaßung eine Toleranz hinzuzufügen. -

Sobald eine Toleranz gesetzt ist, klicken Sie auf den Dropdown-Pfeil (

), um die Toleranzparameter festzulegen:

), um die Toleranzparameter festzulegen:

-

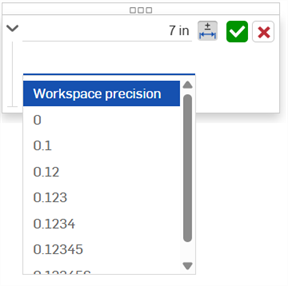

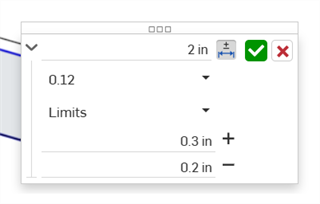

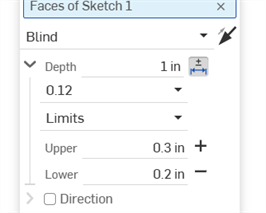

Genauigkeit: Verwenden Sie das Dropdown-Menü, um eine Einheitengenauigkeit auszuwählen. Sie können entweder die Arbeitsbereich-Genauigkeit oder einen anderen Genauigkeitswert aus der Dropdown-Liste mit 0 bis 6 Dezimalstellen festlegen.

-

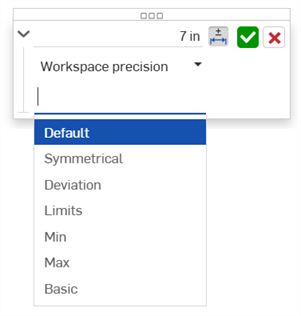

Toleranztyp: Wählen Sie einen Toleranztyp aus der Dropdown-Liste aus: „Standard“, „Keine Toleranz“, „Symmetrisch“, „Abweichung“, „Grenzwerte“, „Min.“, „Max.“ und „Basis“.

Bei den Toleranzen für Bohrung- und Skizzen-Durchmesser gibt es zudem die Optionen „Anpassen“, „Anpassungstoleranz“ und „Anpassen (nur Toleranz)“. Weitere Informationen finden Sie unter Bohrungs-Feature.

Wenn „Standard“ ausgewählt ist, basieren die Toleranzen auf den Standardtoleranzen. Weitere Informationen finden Sie in der Onshape-Standardtoleranzen-Bibliothek und in der Standardtoleranzen-Bibliothek.

-

Abweichung: verfügbar für den symmetrischen Toleranztyp. Geben Sie einen Abweichungswert ein.

-

Obere: verfügbar für die Toleranztypen „Abweichung“ und „Grenzwerte“. Geben Sie den Wert für die obere Toleranz ein.

-

Untere: verfügbar für die Toleranztypen „Abweichung“ und „Grenzwerte“. Geben Sie den Wert für die untere Toleranz ein.

-

Standard: verfügbar für die Toleranztypen „Anpassen“, „Anpassungstoleranz“ und „Anpassen (nur Toleranz)“. Wählen Sie die ANSI- oder ISO-Norm in der Dropdown-Liste aus.

- Anpassungstyp: verfügbar für die Toleranztypen „Anpassen“, „Anpassungstoleranz“ und „Anpassen (nur Toleranz)“. Wählen Sie in der Dropdown-Liste eine Option aus: „Benutzerdefiniert“, „Abstand“, „Umstellung“ oder „Interferenz“.

- Bohrungsklasse: verfügbar für die Toleranztypen „Anpassen“, „Anpassungstoleranz“ und „Anpassen (nur Toleranz)“. Wählen Sie in der Dropdown-Liste die Option „Bohrungsklasse“ aus.

- Wellenklasse: verfügbar für die Toleranztypen „Anpassen“, „Anpassungstoleranz“ und „Anpassen (nur Toleranz)“. Wählen Sie eine Wellenklasse aus der Dropdown-Liste aus.

-

-

-

Klicken Sie auf das Häkchensymbol (

), um die im Kontext-Dialogfenster eingegebenen Werte zu akzeptieren.

), um die im Kontext-Dialogfenster eingegebenen Werte zu akzeptieren. -

Klicken Sie auf das X-Symbol (

), um das Kontext-Dialogfenster ohne Änderungen zu verlassen.

), um das Kontext-Dialogfenster ohne Änderungen zu verlassen. -

Klicken Sie und ziehen Sie bei gedrückter Maustaste am Griff des Dialogfensters (

), um das Dialogfenster an eine andere Stelle auf dem Bildschirm zu verschieben. Lassen Sie die Maustaste los, um es an seiner neuen Position zu platzieren.

), um das Dialogfenster an eine andere Stelle auf dem Bildschirm zu verschieben. Lassen Sie die Maustaste los, um es an seiner neuen Position zu platzieren.

Für die folgenden Skizzenbemaßungen können Toleranzen verwendet werden:

-

Abstand zwischen zwei Linien

-

Abstand zwischen zwei Punkten

-

Abstand zwischen Skizzengeometrie und einer Ebene

-

Diagonaler Abstand

-

Durchmesser

-

Winkel

-

Direkter Abstand

-

Linearer Abstand

-

Radius

Für die folgenden Skizzenbemaßungen können keine Toleranzen verwendet werden:

-

Einzeiliger Abstand

-

Bogenlänge

-

Mittellinienbemaßungen

Weitere Informationen finden Sie unter Skizzen-Bemaßungstools.

-

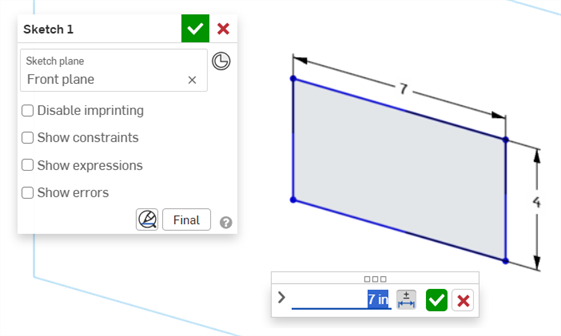

Zeichnen Sie das Skizzenelement und geben Sie beliebige Werte in die dann verfügbaren Eingabefelder für Werte ein.

-

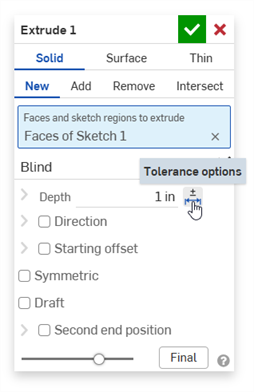

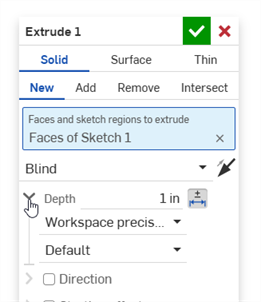

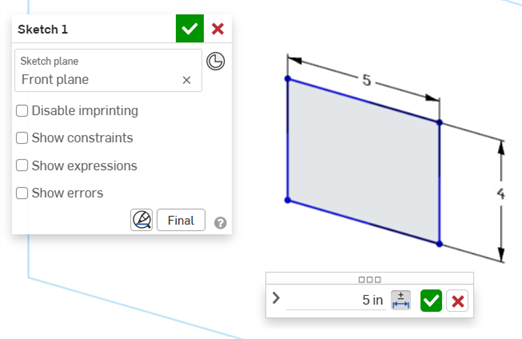

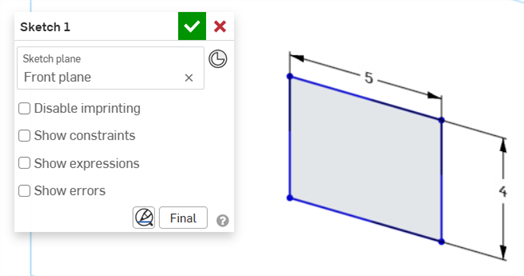

Doppelklicken Sie auf die Bemaßung (1.Bild unten). Das Dialogfenster „Bemaßungskontext“ wird geöffnet (2. Bild unten):

-

Um der Bemaßung eine Toleranz hinzuzufügen, klicken Sie auf das Symbol „Toleranzoptionen“ (

, 1. Bild unten) und dann auf den Dropdown-Pfeil (

, 1. Bild unten) und dann auf den Dropdown-Pfeil ( , 2. Bild unten):

, 2. Bild unten):

-

Geben Sie die konkreten Werte für die Genauigkeit und den Toleranztyp ein:

-

Klicken Sie auf das Häkchen (

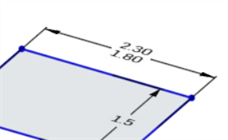

), um die neue Skizzen-Bemaßung zu akzeptieren:

), um die neue Skizzen-Bemaßung zu akzeptieren:

Die folgenden Feature-Optionen können Toleranzen verwenden:

-

Linear austragen

-

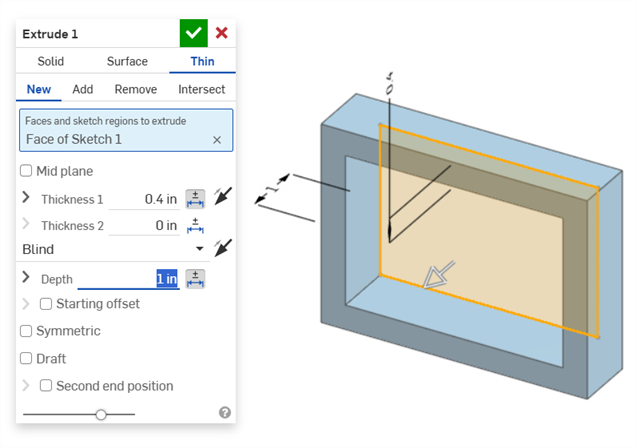

Volumenkörper/Oberfläche/Dünn – Tiefe

-

Volumenkörper/Oberfläche/Dünn – Versatz-Abstand

-

Volumenkörper/Oberfläche/Dünn – Zweite Endposition – Versatz-Abstand

-

Dünn – Dicke 1

-

Dünn – Dicke 2

-

Dünn – Mittige Ebene – Dicke

-

-

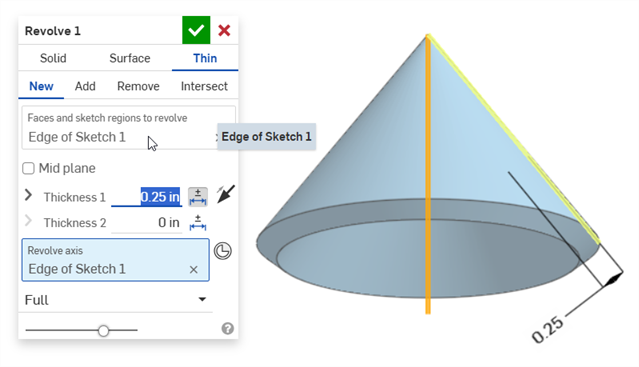

Rotieren

-

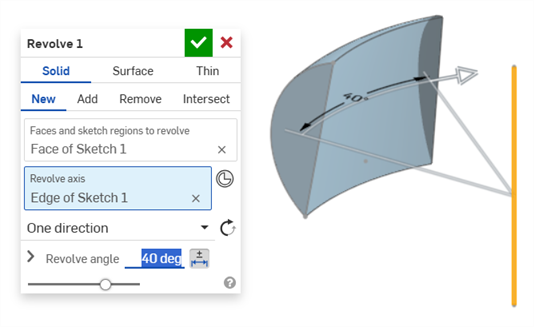

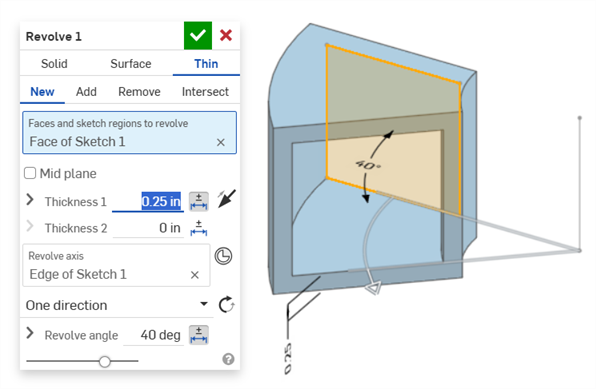

Volumenkörper/Oberfläche/Dünn – Eine Richtung/Symmetrisch/Zwei Richtungen – Rotierwinkel

-

Thin - Thickness 1

-

Dünn – Dicke 2

-

Dünn – Mittige Ebene – Dicke

-

-

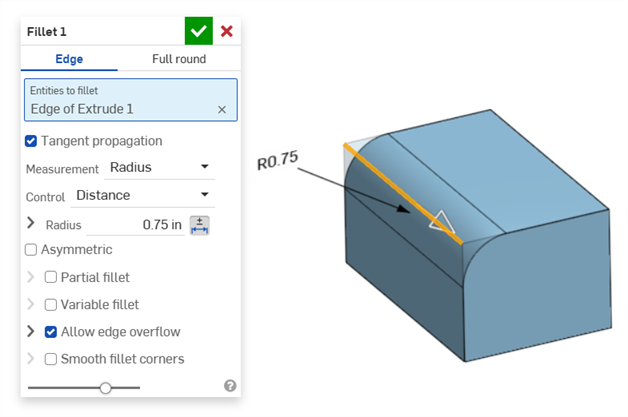

Verrundung

-

Radius

-

-

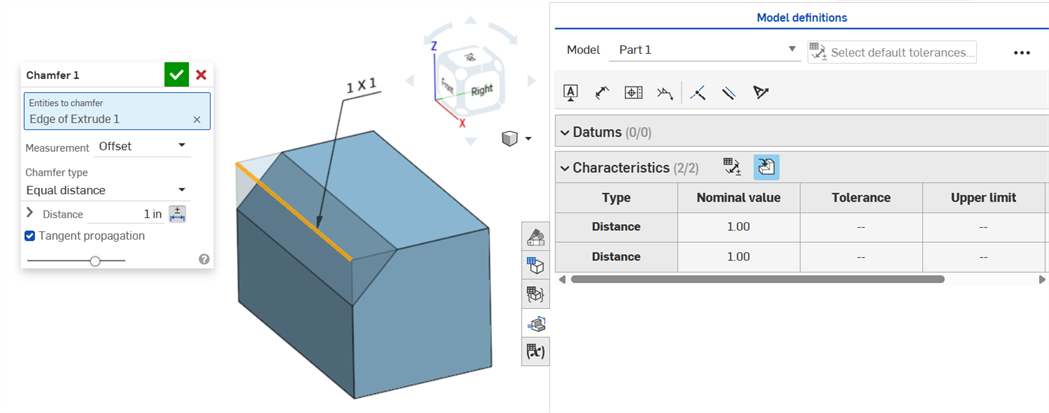

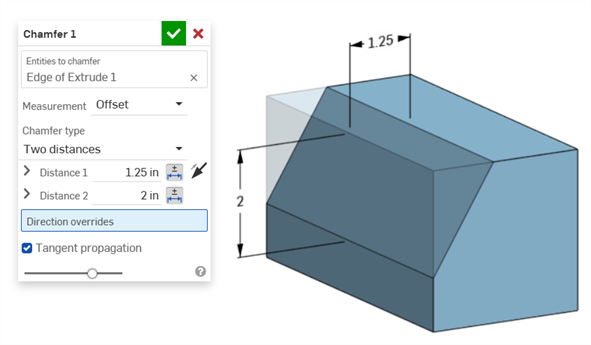

Fase

-

Abstand (Gleicher Abstand)

-

Abstand 1, Abstand 2 (zwei Abstände)

-

Abstand und Winkel (Abstand, Winkel)

-

-

Bohrung

-

Durchmesser (Einfach/Stirnsenkung/Formsenkung)

-

Abstand (Tiefe: Einfach/Stirnsenkung/Formsenkung)

-

Durchmesser (Stirnsenkungs-/Formsenkungsdurchmesser)

-

Abstand (Stirnsenkungstiefe)

-

Winkel (Formsenkungswinkel)

-

Thread class

-

Tapped depth

-

Tap drill diameter

-

-

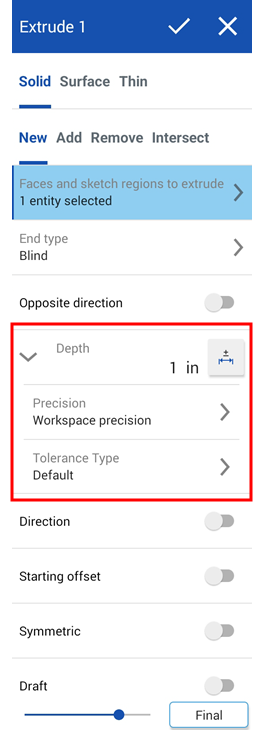

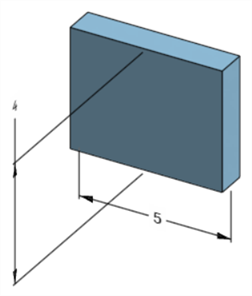

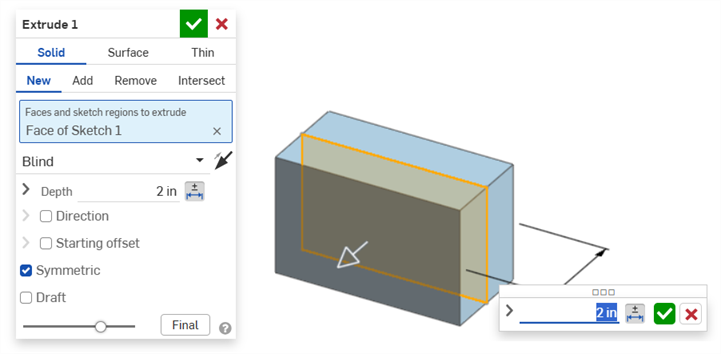

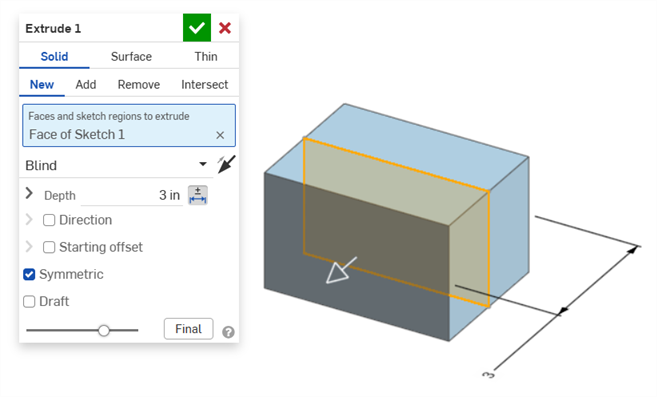

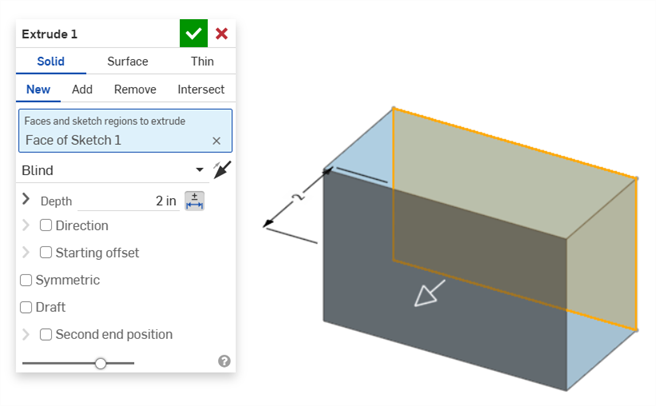

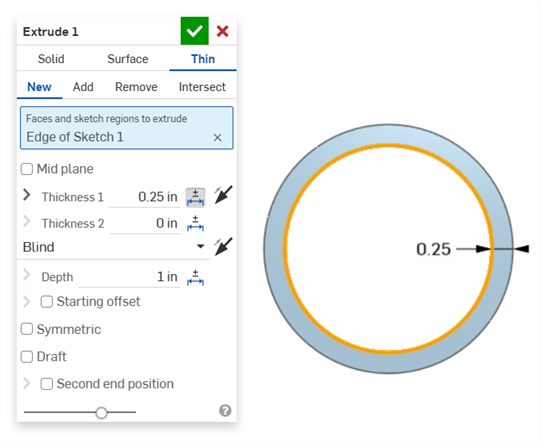

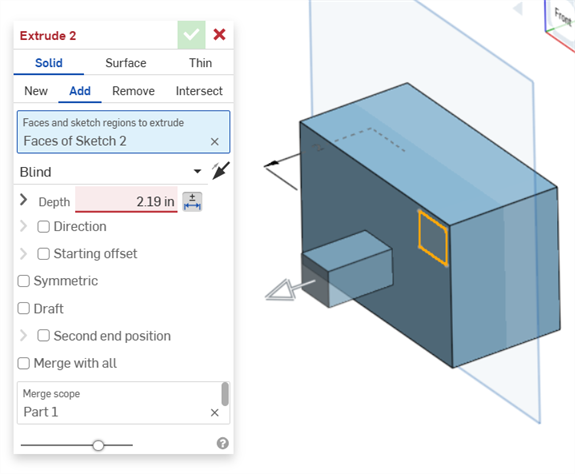

Erstellen Sie ein Feature, das eine Toleranz akzeptiert (in diesem Beispiel „Linear austragen“).

-

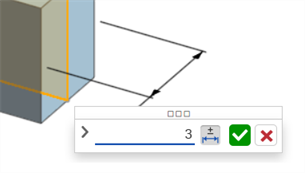

Klicken Sie auf das Symbol „Toleranzoptionen“ (

) rechts neben dem Parameter:

) rechts neben dem Parameter:

-

Klicken Sie auf den Dropdown-Pfeil (

) links neben dem Parameter:

) links neben dem Parameter:

-

Geben Sie die konkreten Werte für die Genauigkeit und den Toleranztyp ein:

-

Geben Sie weitere Feature-Einstellungen ein und klicken Sie auf das Häkchen (

), um das Feature zu akzeptieren.

), um das Feature zu akzeptieren. -

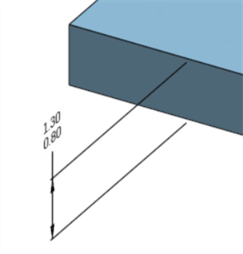

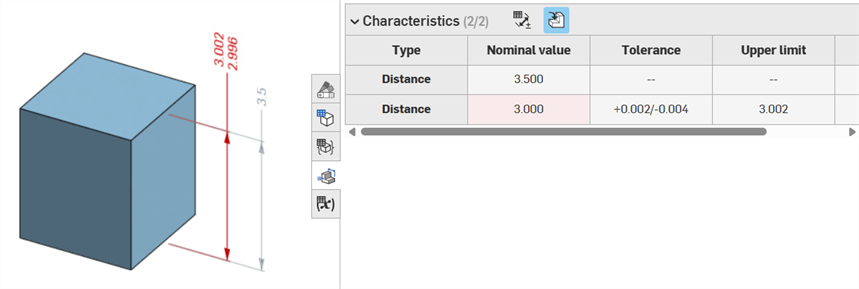

Stellen Sie sicher, dass die Prüfungstabelle (

) geöffnet ist, damit Sie den Bemaßungswert des Features mit der Toleranz sehen können:

) geöffnet ist, damit Sie den Bemaßungswert des Features mit der Toleranz sehen können:

Wenn Sie die Toleranz eines Features entfernen, wird die Bemaßung nicht aus dem Modell entfernt, da sie immer noch eine gültige Bemaßung ist.

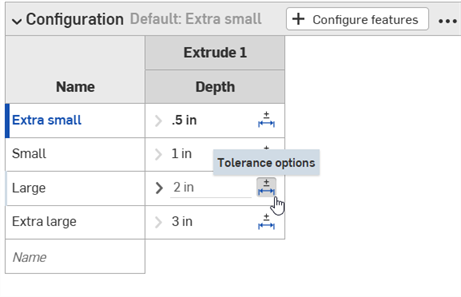

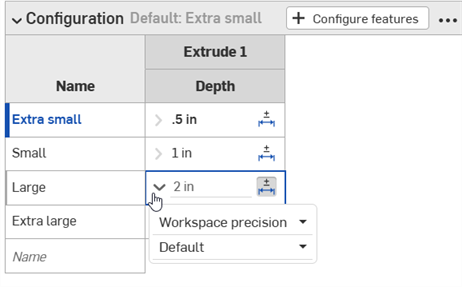

Tolerance options can be used in conjunction with configurations.

-

Click the Tolerance options icon (

) to make the configuration's option value tolerant:

) to make the configuration's option value tolerant:

-

Click the dropdown arrow icon (

) to the left of the parameter in order to set the tolerance Precision and Type.

) to the left of the parameter in order to set the tolerance Precision and Type.

See Configurations for more information.

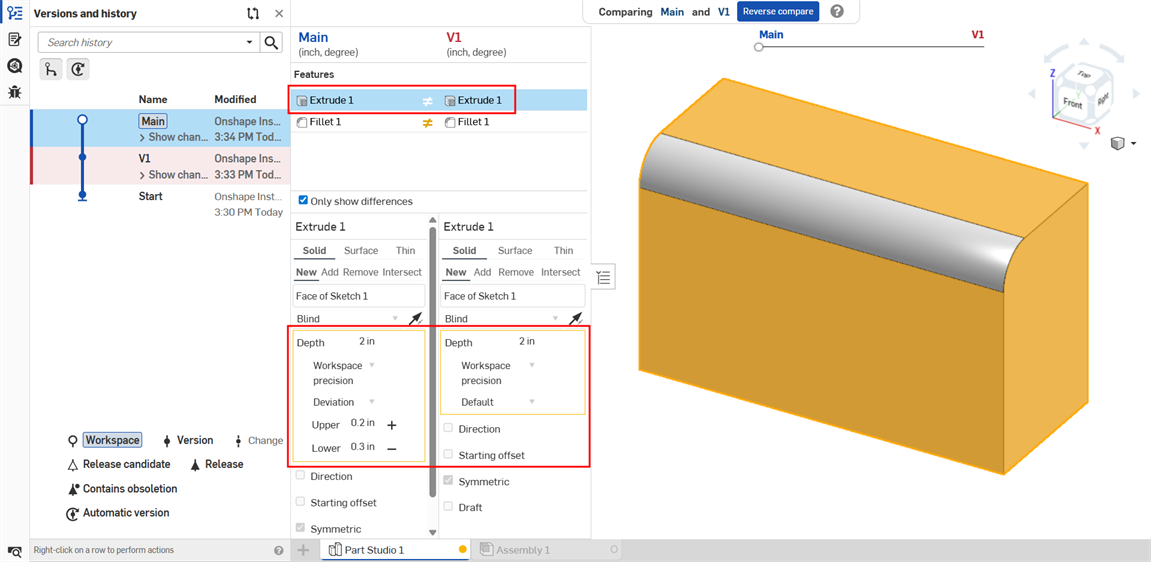

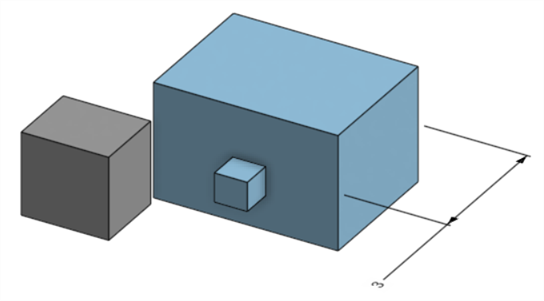

Tolerance options are automatically used in conjunction with the Compare mechanism. When comparing 2 history entries, select the Feature to compare (Extrude 1 in the example below). Comparisons between differing Tolerance options in the entries are outlined in yellow:

Extrude: Depth tolerance options compared between two history entries

See Compare for more information.

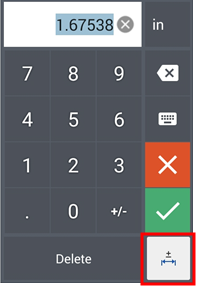

Sketch dimension tolerances:

-

Double-tap the dimension on-screen.

-

Click on the Tolerance options button at the lower right corner of the Android Dimension context dialog to set the dimension as tolerant:

-

In the Tolerance options dialog, enter the Precision and/or Tolerance type and click the checkmark to accept the options:

Feature dimension tolerance:

Feature dimensions can be set and edited in the same way as on the desktop platform:

Tolerance options for the Extrude: Depth value

Tolerances can only be viewed on the desktop platform, not Android, since the Inspection table is available only on desktop.

Tolerance options are not currently available on iOS. Use the desktop platform to set, edit, and view Tolerance options.

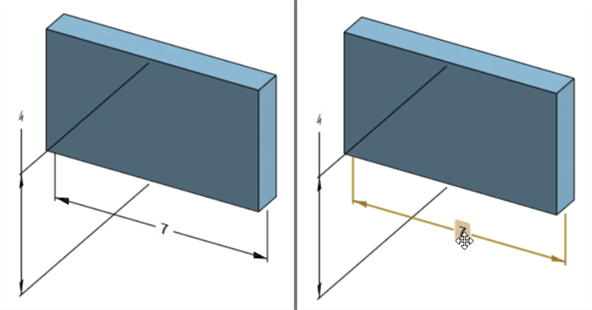

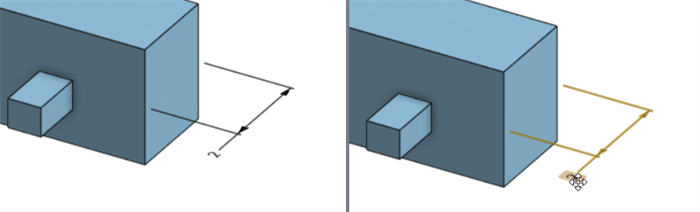

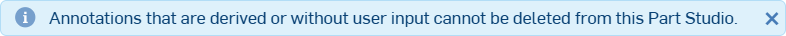

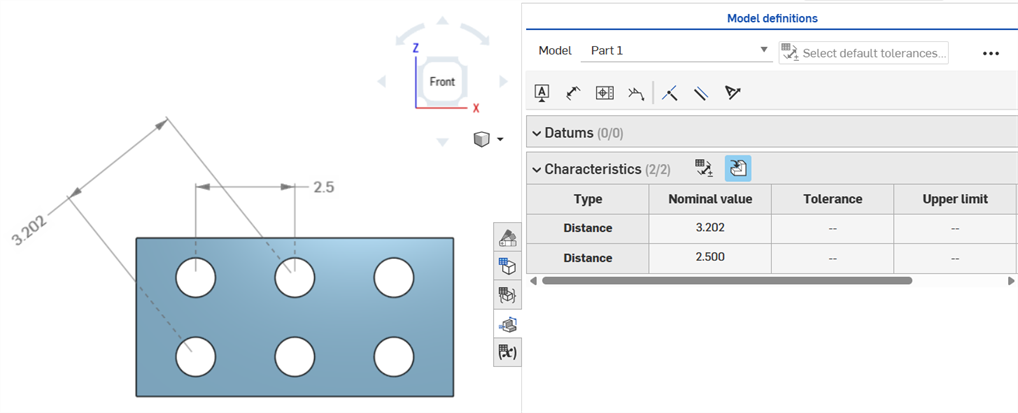

Driving MBD sketch and feature dimensions can be edited directly from the graphics area.

-

Open the Inspection panel (

) to display the MBD dimensions in the graphics areas (left image below).

) to display the MBD dimensions in the graphics areas (left image below). -

Double-click on the driving dimension that is associated with a sketch (right image below):

The Dimension context dialog opens with context placed on the dimension value. Simultaneously, the Sketch dialog opens:

-

Using the keyboard, enter a numeric value or use the up/down arrows to increment the value in the Dimension context dialog. As this value is adjusted, the sketch is updated dynamically.

If entering a value numerically, press the tab key to see the sketch value update.

-

Press Enter on the keyboard or click the checkmark (

) in the Dimension context dialog to close this dialog:

) in the Dimension context dialog to close this dialog:

-

Press the checkmark (

) in the Sketch dialog to accept the new sketch value.

) in the Sketch dialog to accept the new sketch value.

The edited sketch dimension that adjusts the model's dimension

-

Open the Inspection panel (

) to display the MBD dimensions in the graphics areas (left image below).

) to display the MBD dimensions in the graphics areas (left image below). -

Double-click on the driving dimension that is associated with a feature (right image below):

The Dimension context dialog opens with context placed on the dimension value. Simultaneously, the associated Feature dialog opens (Extrude in this example):

-

Using the keyboard, enter a numeric value or use the up/down arrows to increment the value in the Dimension context dialog. As this value is adjusted, both the model and the value in the Feature dialog are updated dynamically.

If entering a value numerically, press the tab key to see the value update in the Feature dialog.

-

Press Enter on the keyboard or click the checkmark (

) in the Dimension context dialog to close this dialog:

) in the Dimension context dialog to close this dialog:

-

Press Enter on the keyboard again or click the Feature dialog checkmark (

) to close this dialog:

) to close this dialog:

The edited feature dimension that adjusts the model's dimension

To delete an annotation:

-

Select the annotation in the graphics area:

-

Press the Delete key.

-

The Annotation is deleted from the graphics area and Inspection table.

If the annotation is a sketch or feature dimension:

-

The dimension's Tolerance options values are deleted.

-

The Tolerance options icon (

) is deselected.

) is deselected. -

The dimension value in the sketch or Feature dialog is not deleted.

-

Annotations cannot be deleted if:

-

The annotation is derived.

-

The annotation is created in a custom feature where the parameter is made tolerant but the tolerant toggle is not made available for user input.

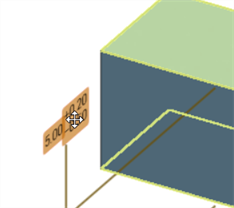

In either case the following message is displayed:

-

Driven dimensions cannot be edited. Double-clicking on a driven dimension opens the Dimension context dialog, but values in the dialog cannot be edited.

-

Derived dimensions cannot be edited. Double-clicking on a driving or driven dimension from a derived part does not open the Dimension context dialog.

-

To cancel out of the Dimension context dialog, press the Esc key. If editing a feature dimension, the Dimension context dialog and Feature dialog close simultaneously. If editing a sketch dimension, only the Dimension context dialog closes. The sketch dialog must be manually closed (clicking the x icon).

-

Alternatively, with both the Feature dialog and Dimension context dialog open, the value in the Feature dialog can be selected and edited, which updates both the Dimension context dialog and model dynamically. Once edited here, pressing Enter closes both the Feature dialog and the Dimension context dialog simultaneously.

-

The location of the model dimension and location of its corresponding sketch dimension are not locked together. They are independent:

The model's width dimension is located below the model (left) but above the sketch (right)

-

In Pause regeneration mode, the model's dimension cannot be edited or deleted. However, you can still edit the feature or toggle a dimension's tolerance on or off. Changes take effect after clicking the Regenerate features and exit checkmark on the Paused regeneration banner.

-

Configurations work as expected. However, the dimension in the Dimension context dialog is not surrounded by a dashed orange outline to indicate it is configured. Configured sketch dimensions cannot be edited.

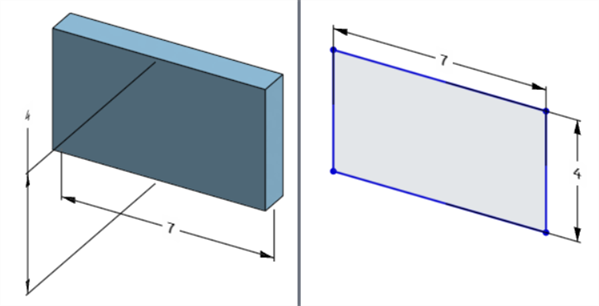

MBD data can be exported to Step file format. The following settings are recommended:

-

Enable the Export models oriented Y axis up checkbox.

-

Depending on the size of your model, you may need to enable the Use custom annotation text height for MBD export and select an appropriate Annotations text height to correspond to your model size.

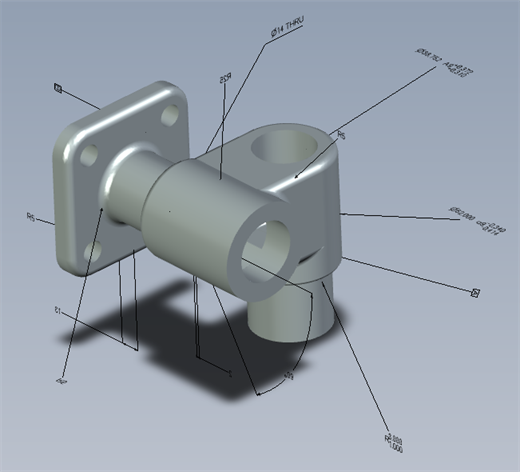

Original model in Onshape

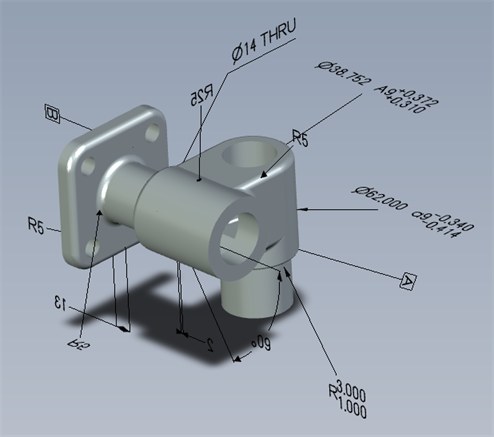

Exported model with the "Use custom annotation text height for MBD export" option disabled

Exported model with the "Use custom annotation text height for MBD export" enabled and set to 10 mm.

When exported, Geometric tolerances with multiple Tolerance frames have Upper text combined with the top frame, and Lower text combined with the bottom frame.

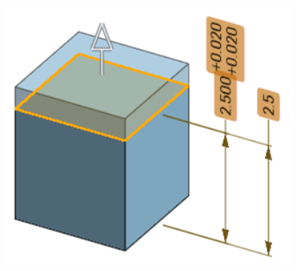

The following provides MBD examples when working with Feature and dimension tolerances:

Depth dimension:

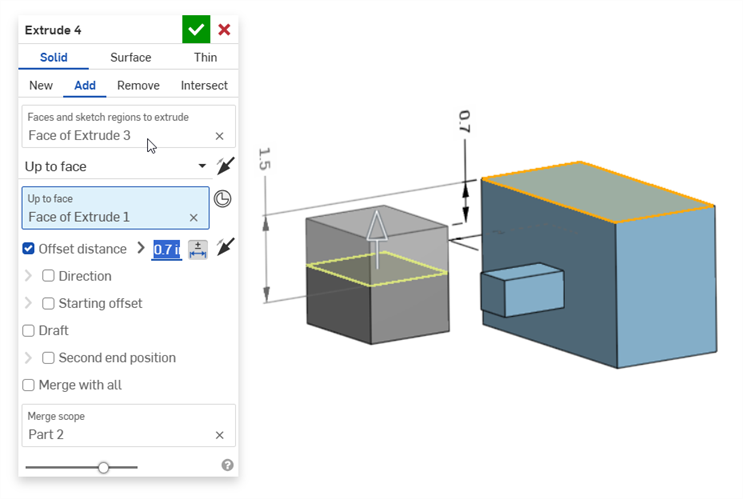

Offset distance dimension (with a composite part):

Thin extrude (Thickness 1 and Depth dimensions):

Revolve (Revolve angle dimension):

Revolve (Thickness 1 and Revolve angle dimensions):

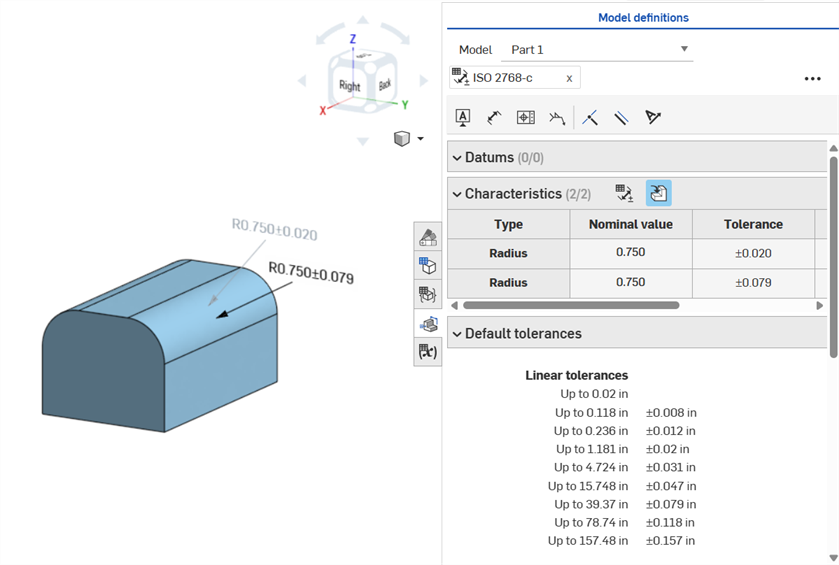

Fillet (Radius dimension):

Since default tolerances always use linear or angular dimensions, adding a dimension using the Inspection panel's Dimension tool (![]() ) with a Default tolerance type always generates a linear or angular tolerance value, even if the face is a fillet. For this reason, it is recommended to apply fillet tolerances from the feature dialog, and not from the Inspection panel.

) with a Default tolerance type always generates a linear or angular tolerance value, even if the face is a fillet. For this reason, it is recommended to apply fillet tolerances from the feature dialog, and not from the Inspection panel.

Dimensioning a fillet face: From the Fillet feature dialog (driving) and from the Inspection panel (driven)

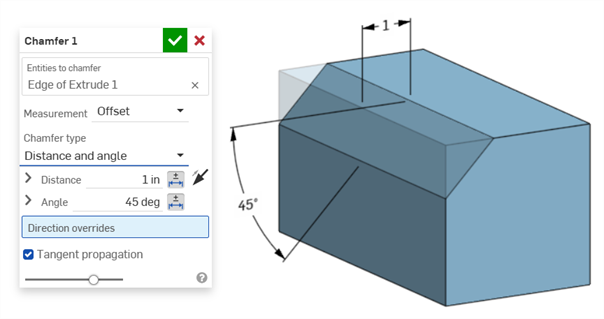

A Chamfer is defined as a distance to angle or distance to distance between a face and an edge. The Chamfer width dimensions are specified as the distance from an edge to the virtual sharp. The display for virtual sharps is added to the dimensioned edge, including a dashed curve.

-

Tolerances are not disabled When a tangent measurement is used, since they can work in certain cases, and especially when accounting for the specified tolerance.

-

In situations where two chamfer measurements are used (Two distances or Distance and angle), the user does not have to create tolerances for both. Tolerances can be added to only one parameter, if required.

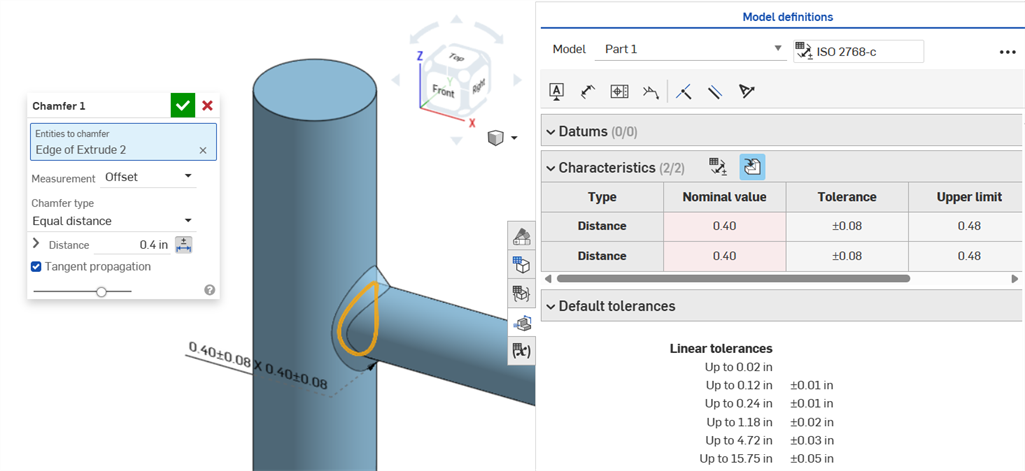

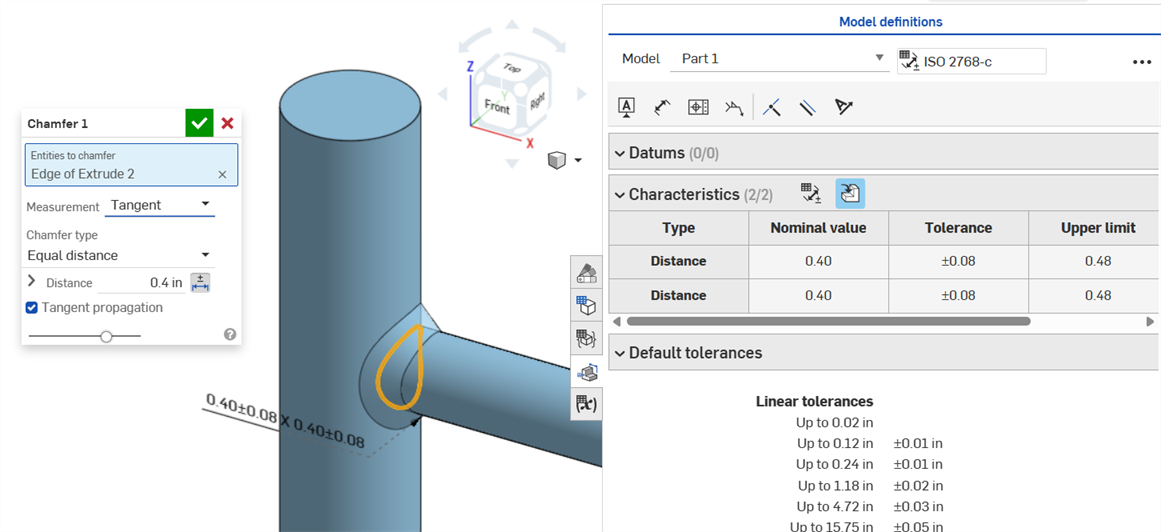

Equal distance Chamfer type displays 2 Distance tolerance values, which are reflected in the table, even though there is only one distance tolerance option in the dialog:

Two distances example:

Distance and angle example:

For cases where the chamfer results in a variable distance (for example, if the chamfer is applied to a cylinder face that is perpendicularly connected to another cylinder), try selecting tangent for the Measurement, to make the distance uniform along the edge:

Non-uniform chamfer using an Offset measurement displaying a Nominal value error.

Uniform chamfer using a Tangent measurement results in a Nominal value without error.

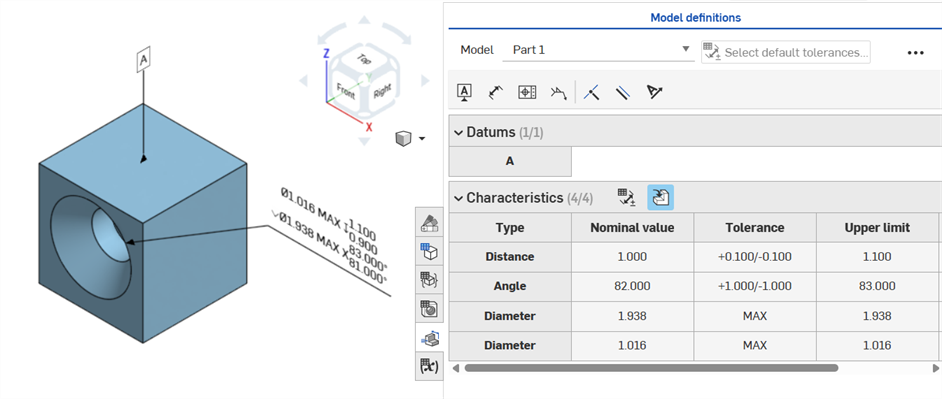

If a tolerance is placed on a hole feature, it can be displayed in the Inspection table. Hole tolerances can display

-

Diameter (Simple/Counterbore/Countersink)

-

Distance (Depth: Simple/Counterbore/Countersink)

-

Dameter (Counterbore/Countersink diameter)

-

Distance (Counterbore depth)

-

Angle (Countersink angle)

Some things to keep in mind:

-

Hole dimensions are only visible as rows in the Inspection table. There are no dimensions placed in the graphics area. This is done so as not to clutter the graphics area with callouts.

-

Before hole dimensions are visible in the Inspection table, another callout (a datum, for example) must be placed on the part.

-

Only one set of dimensions (Diameter, Distance, and/or Angle) are shown per hole feature. Patterned holes or additional holes in the same feature are not dimensioned separately.

-

The custom Tip angle dimension is not currently supported and does not create a row in the Inspection table.

-

Cross-highlighting works as follows:

-

Distance (Depth) is not cross-highlighted because there are no faces at either end of the hole, and edges are not currently supported for MBD.

-

Diameter, Distance (Counterbore depth), and Angle (Countersink angle) cross-highlights a single face.

-

Hole dimensions are visible in the Inspection table after a Datum is added to one of the part's faces.

Axis distance dimensions between center circles:

Thickness is displayed in the Inspection table as a Distance row.

Thin extrude (Thickness 1 dimension):

Thin revolve (Thickness 1 dimension):

MBD errors do not create annotations or row entries in the Inspection table, unless an adjustment to the model is made that invalidates an existing annotation row entry.

Errors are displayed in red, similar to other Onshape errors:

Error generated when extruding from or into a solid. The annotation does not generate a row entry in the Inspection table.

If the geometry is altered so as to invalidate a specified annotation, its corresponding annotation is red in the graphics area, and highlighted red in the Inspection table, signaling an error. For example, The top face of the box was moved .5 in., resulting in the measured value (3.5 in.) differing from the specified value (3.0 in.):

Error examples

-

A reference is missing for this annotation - Occurs when a reference is missing. For example, Part A is extruded up to the face of part B, and a tolerance is added to the Offset distance of the Part A extrusion.

-

Both faces must be from the same part - Model definitions are valid only on a per-part basis. For example, you cannot dimension the distance from a face on Part A to a face on Part B.

-

MBD annotations must always be associated with faces. Edges and vertices cannot currently be referenced.

-

Model definitions are valid only on a per-part basis. Composite parts are also valid. For example, you can dimension the distance between 2 faces on Part A or 2 faces on Part B, but not between a face on Part A and a face on Part B. To do this, first create a composite Part C from both Part A and Part B. You can then dimension the distance between these 2 faces.

-

Hovering over the Type row in the Inspection table cross-highlights the dimension in the graphics area.

-

When altering geometry of a part, all associated model definitions are highlighted orange:

-

If a part or Part Studio is derived via the Derived feature, all model definitions are read-only and cannot be edited. You can still move annotations, and driven dimensions are still updated if the derived geometry is altered; however, the underlying model definitions can only be adjusted in the source Part Studio, and then updated in the Derived Feature. See Derived for more information.