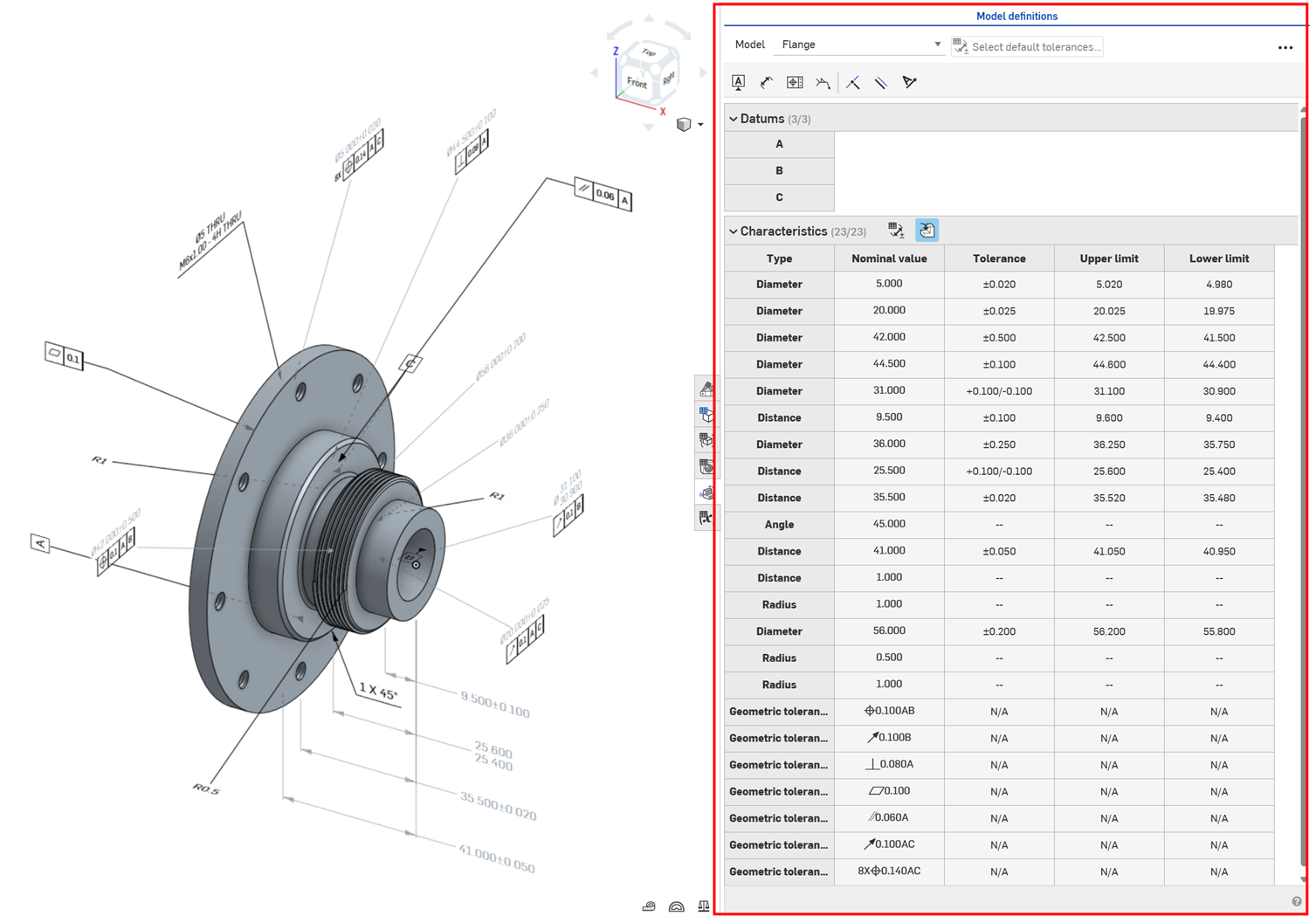

Inspection Table

Inspection Table

![]()

Introduction

Inspect and add model definitions to parts in the Part Studio. These include datums, dimensions, geometric tolerances, and weld symbols. You can also set annotations to be parallel or coincident with faces, and have annotation text aligned with faces or edges.

The Inspection table icon is located on the right side of the graphics area:

- Click the inspection item icon (

) to the right-side of the graphics area (below the View cube):

) to the right-side of the graphics area (below the View cube):

-

The Inspection table opens, showing the Model definitions title at the top.

The following explains the Inspection table interface:

-

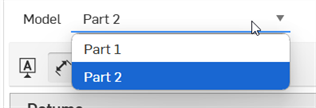

Model - Select a Part in the graphics area where annotations are applied. Use the dropdown to switch between parts in the Part Studio. The Datums and Characteristics tables below switch to display model definitions for the selected part.

-

Variable Studio (

) - Click this button to select Default tolerances for the current Part Studio. See Default tolerances library.

) - Click this button to select Default tolerances for the current Part Studio. See Default tolerances library. -

Annotation toolbar - Use the options on this toolbar to annotate the selected part.

-

Datum (

) - Add a datum to a specific location on a face of the selected part. Multiple datums can be applied to a face. See Datum.

) - Add a datum to a specific location on a face of the selected part. Multiple datums can be applied to a face. See Datum. -

Dimension (

) - Add a dimension to the selected part. See Dimension.

) - Add a dimension to the selected part. See Dimension. -

Geometric tolerance (

) - Often associated with datum, use Geometric tolerance to create and place basic dimension notations to the selected part. See Geometric tolerance.

) - Often associated with datum, use Geometric tolerance to create and place basic dimension notations to the selected part. See Geometric tolerance. -

Weld symbol (

) - Add a Weld symbol to the face of the selected part. See Weld symbol.

) - Add a Weld symbol to the face of the selected part. See Weld symbol. -

Set coincident (

) - Set the annotation coincident to a part's face. See Set coincident.

) - Set the annotation coincident to a part's face. See Set coincident. -

Set parallel (

) - Sets a parallel constraint to make 2 or more selected part entities parallel. See Set parallel.

) - Sets a parallel constraint to make 2 or more selected part entities parallel. See Set parallel. -

Set text alignment (

) - Set the annotation's text to align to the part's edge or face. See Setting text alignment. See Set text alignment.

) - Set the annotation's text to align to the part's edge or face. See Setting text alignment. See Set text alignment.

-

-

Datums table - Lists a row for each Datum associated with the selected part.

-

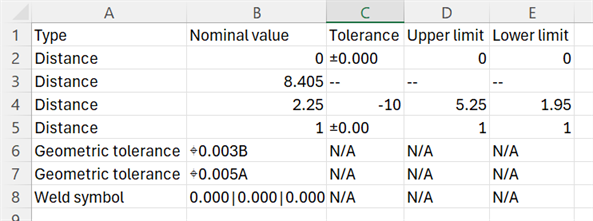

Characteristics table - Lists a row for each Inspection item associated with the selected part. Columns display the Type (Distance, Diameter, Angle, Geometric tolerance, Weld symbol), Nominal value, Tolerance, Upper limit, and Lower limit for each inspection item.

-

Filters - Toggle buttons used to filter the Characteristics table. Useful for a highly complex part with many annotations:

-

Show/hide default tolerances (

) - Filters the Characteristics table to display or hide default tolerances.

) - Filters the Characteristics table to display or hide default tolerances. -

Show/hide derived tolerances (

) - Filters the Characteristics table to display or hide derived tolerances.

) - Filters the Characteristics table to display or hide derived tolerances.

By default, Default tolerances are shown and Derived tolerances are hidden.

-

-

-

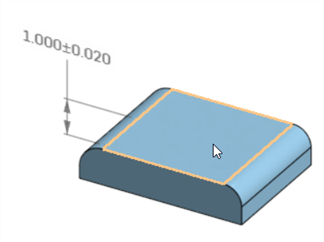

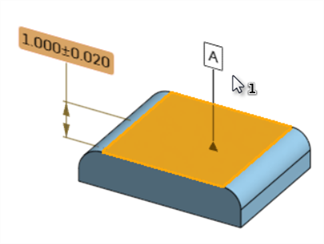

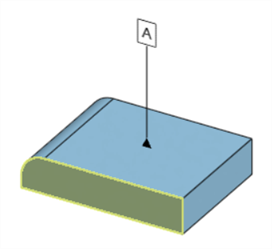

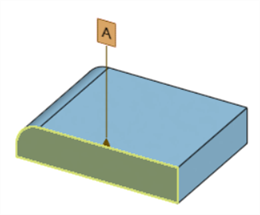

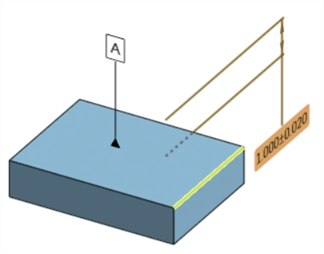

Click the Datum icon (

) on the Annotation toolbar. The Datum dialog opens:

) on the Annotation toolbar. The Datum dialog opens:

-

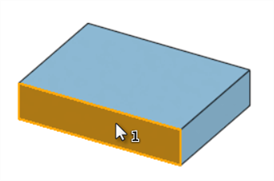

Click a face location on the part:

-

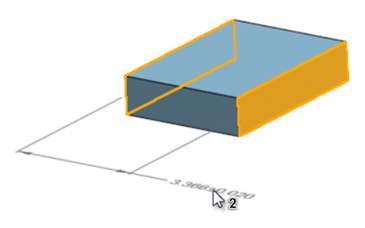

Drag the Datum to extend the leader line and Datum to a specified location:

-

Optionally, edit the datum Identifier in the Datum dialog. The first datum added to a part defaults to A, the next to B, then C, and so forth.

-

Click the checkmark (

) to accept, or cancel (

) to accept, or cancel (  ) to exit without changes.

) to exit without changes.

Notes

-

To edit any datum, double-click it. The Datum dialog opens. Make any adjustments as required.

-

Multiple datums can be applied to a face.

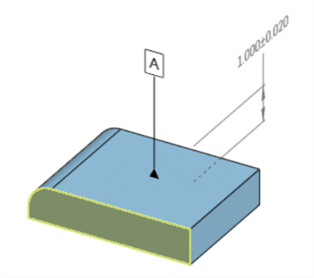

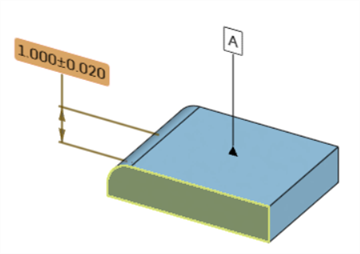

Click the Dimension icon (![]() ) on the Annotation toolbar.

) on the Annotation toolbar.

-

Click a face on the part:

-

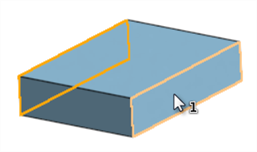

Click a second face on the part:

-

The dimension is created. Drag the dimension to extend its leader lines to a specified location.

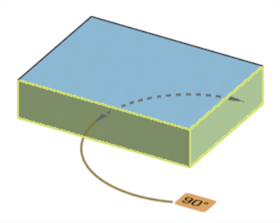

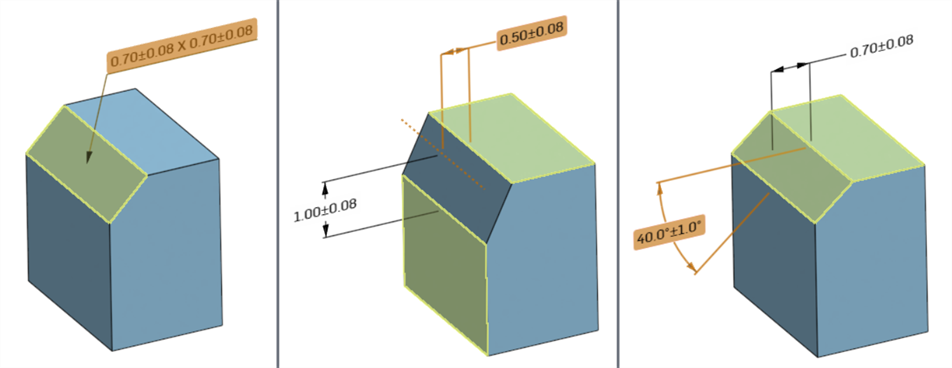

Example selecting 2 adjacent faces to create an angle dimension:

Notes

-

To edit any dimension's tolerance, double-click it. The dimension context dialog opens. Make any adjustments as required:

-

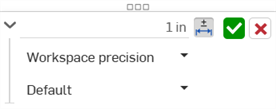

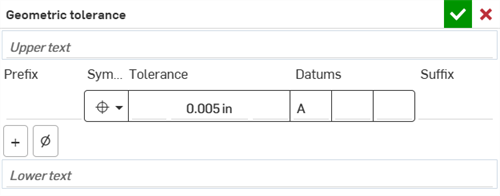

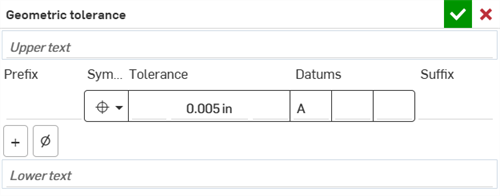

Click the Geometric tolerance icon (

) on the Annotation toolbar. The Geometric tolerance dialog opens:

) on the Annotation toolbar. The Geometric tolerance dialog opens:

-

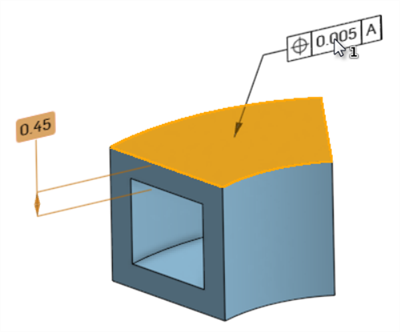

Either:

-

Click a face location on the part to attach the Geometric tolerance to that face.

Drag the Geometric tolerance to extend the tolerance and leader line to a specified location in the graphics area.

Left click to place the Geometric tolerance:

-

Click a dimension on the part to attach the Geometric tolerance to that dimension.

Drag the dimension and Geometric tolerance together as a group to place it at a specified location in the graphics area.

The geometric tolerance can be moved in the graphics area during creation or after the Geometric tolerance dialog is closed.

-

-

Enter specifications for the Geometric tolerance in the Geometric tolerance dialog:

-

Upper/Lower text field - Add information above or below the Geometric tolerance.

-

Prefix/Suffix - Enter a Prefix or Suffix to add information to the left or right of the Geometric tolerance frame, respectively.

-

Tolerance frame

- Symbol (Geometric tolerance type) - Select the type of Geometric tolerance from this dropdown field. The symbol is placed to the left of the Geometric tolerance. Options are: Position, Concentricity, Symmetry, Parallelism, Perpendicularity, Angularity, Cylindricity, Flatness, Roundness, Straightness, Profile (Surface), Profile (Line), Circular runout, and Total runout.

- Tolerance - Enter a tolerance value. Optionally, enter text or symbols in fields to the left and/or right of the tolerance value.

- Datums - Enter up to 3 datum values in the 3 Datum fields.

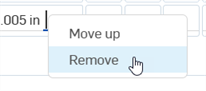

- Add frame - Click the Add frame icon (

) to add an additional constraint row to the table. Up to 5 constraints can be added to the Geometric tolerance. Change the bottom symbol to Composite to create a composite frame.

) to add an additional constraint row to the table. Up to 5 constraints can be added to the Geometric tolerance. Change the bottom symbol to Composite to create a composite frame.To move or remove a constraint line, right-click anywhere on the cells in that line and select either Move up/down (to move the constraint up/down one row in the table) or Remove (to remove the constraint row from the table). This can only be performed on additional constraint rows.

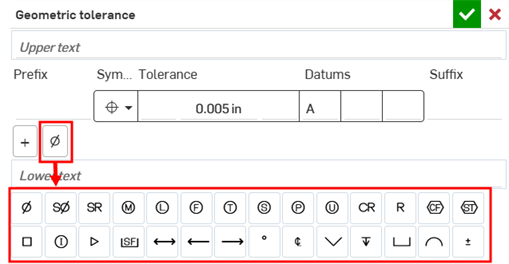

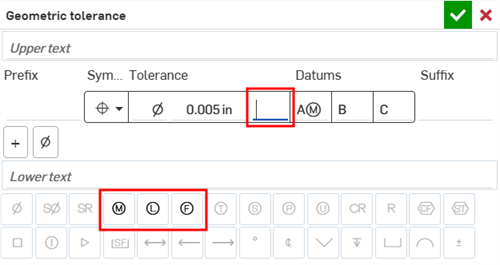

- Show/Hide symbols - Click the Show symbols icon (ø) to open a table of symbols that can be inserted into the Geometric tolerance fields. When in the Upper/Lower text and Prefix/Suffix fields, all symbols are available:

If you are in a field inside the Tolerance frame, the combination of Geometric symbol type and a particular field determines the symbols available for use. For example, in the field after the Tolerance value, the following symbol options are available:

-

-

Click the checkmark (

) to accept, or cancel (

) to accept, or cancel (  ) to exit without changes.

) to exit without changes.

Notes

-

To edit any geometric tolerance, double-click the tolerance. The Geometric tolerance dialog opens. Make any adjustments as required.

-

Multiple geometric tolerances can be attached to a face, but only one can be attached to a dimension.

-

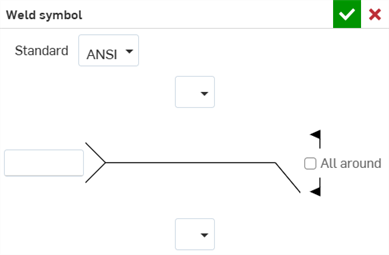

Click the Weld symbol icon (

) on the Annotation toolbar. The Weld symbol dialog opens:

) on the Annotation toolbar. The Weld symbol dialog opens:

-

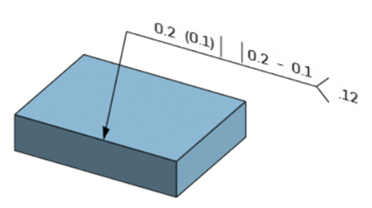

Click a face location on the part to place the Weld symbol.

-

Drag the Weld symbol to extend it and its leader line to a specified location:

-

Enter specifications for the Weld symbol in the Weld symbol dialog:

-

Standard - Select either ANSI or ISO.

-

Flip identification line (ISO Standard only) - When checked, the Weld identification line is flipped to the opposite direction.

-

Weld type (upper or lower) - Select from the following weld types: None, Square groove, V groove, U groove, J groove, Bevel groove, Single bevel butt broad root, V flare groove, Bevel flare groove, Bead joint, Fillet joint, Plug or Slot joint, Seam joint, or Spot joint.

-

Groove (upper or lower) - Enter the degree for the groove, between 0 and 360.

-

Root opening (upper or lower) - Enter the distance for the root opening, in specified measurement units.

-

Finishing (upper or lower; ANSI Standard only) - Select from the following finishings: None, C Chipping, G Grinding, H Hammering, M Machining, R Rotting, or U Unspecified.

-

Contour (upper or lower) - Select from the following contours: None, Flat, Convex, or Concave.

-

Weld size (upper or lower) - Enter the weld size, as a specified distance measurement.

-

Weld depth (upper or lower) - Enter the weld depth, as a specified distance measurement.

-

Weld length (upper or lower) - Enter the weld length, as a specified distance measurement.

-

Weld pitch (upper or lower) - Enter the weld pitch, as a specified distance measurement.

-

- Click the checkmark (

) to accept, or cancel (

) to accept, or cancel (  ) to exit without changes.

) to exit without changes.

Notes

-

To edit any weld symbol, double-click it. The Weld symbol dialog opens. Make any adjustments as required.

-

Multiple weld symbols can be applied to a face.

-

Click the Set coincident icon (

) on the Annotation toolbar.

) on the Annotation toolbar. -

Select a part face:

-

Select the annotation. The annotation is set coincident with the edge of the face:

Notes

-

Once a face is selected, click additional annotations to make them all coincident with the selected face.

-

Faces created by a chamfer or fillet can be selected, but annotations cannot be made coincident with them.

-

Click the Set parallel icon (

) on the Annotation toolbar.

) on the Annotation toolbar. -

Select a part face:

-

Select the annotation. The annotation is set parallel to the face:

Once a face is selected, click additional annotations to set them parallel to the selected face.

-

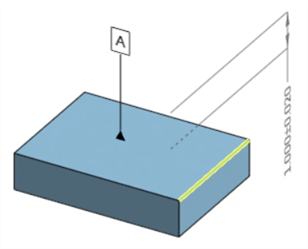

Click the Set text alignment icon (

) on the Annotation toolbar.

) on the Annotation toolbar. -

Select the edge or face on the part:

-

Select the annotation. The annotation text is aligned to the selected edge or face:

Once an edge or face is selected, click additional annotations to align their text to the selected edge/face.

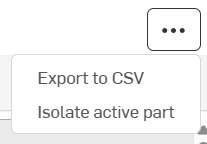

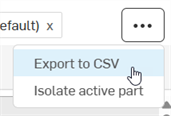

Click the Overflow menu icon (![]() ) at the top right corner of the table accesses the following options:

) at the top right corner of the table accesses the following options:

-

Export to CSV - Exports the table to a CSV file for use in a spreadsheet program like Microsoft Excel or Google Sheets. See Exporting the model's inspection table for more information.

-

Isolate active part / Show entire Part Studio - Isolates the currently active model. When selected, the Isolate dialog opens where you can fine tune the isolation.

If the dialog is still open, accessing this options from the overflow menu displays the Show entire Part Studio option. Selecting this option closes the Isolate dialog and makes all parts in the Part Studio visible.

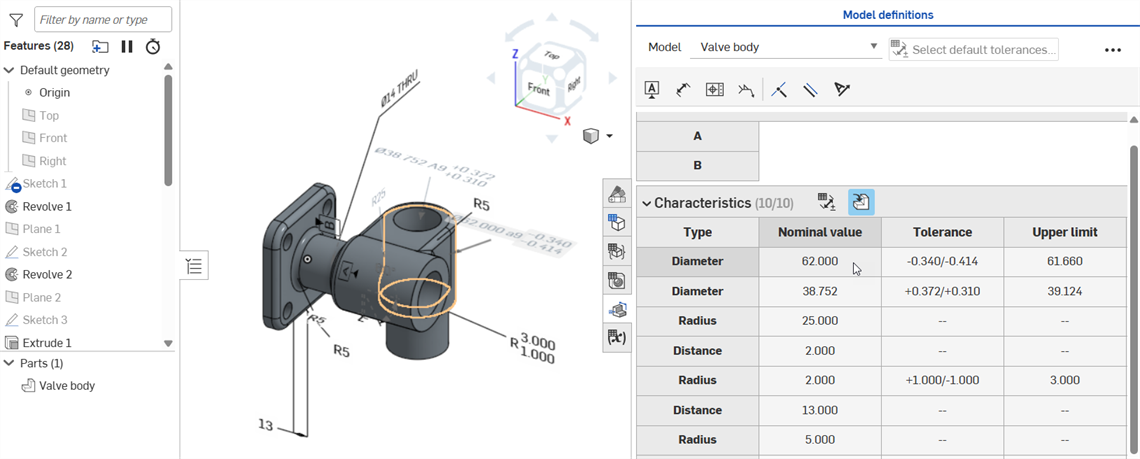

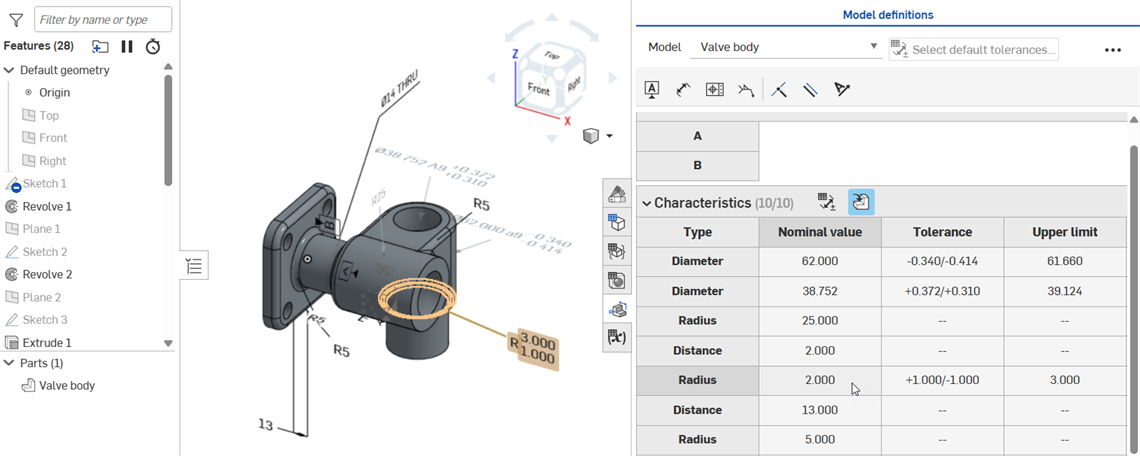

The following explains cross-highlighting from the Inspection table.

-

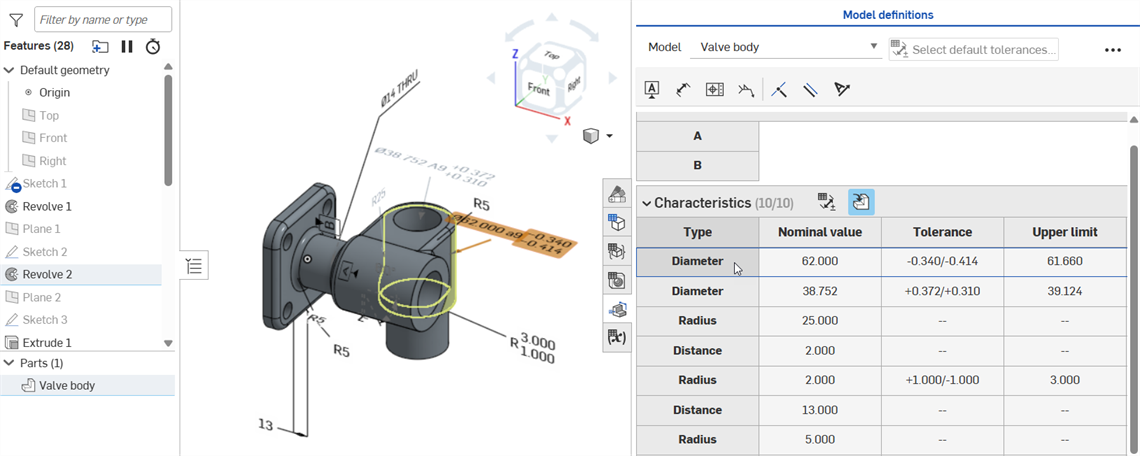

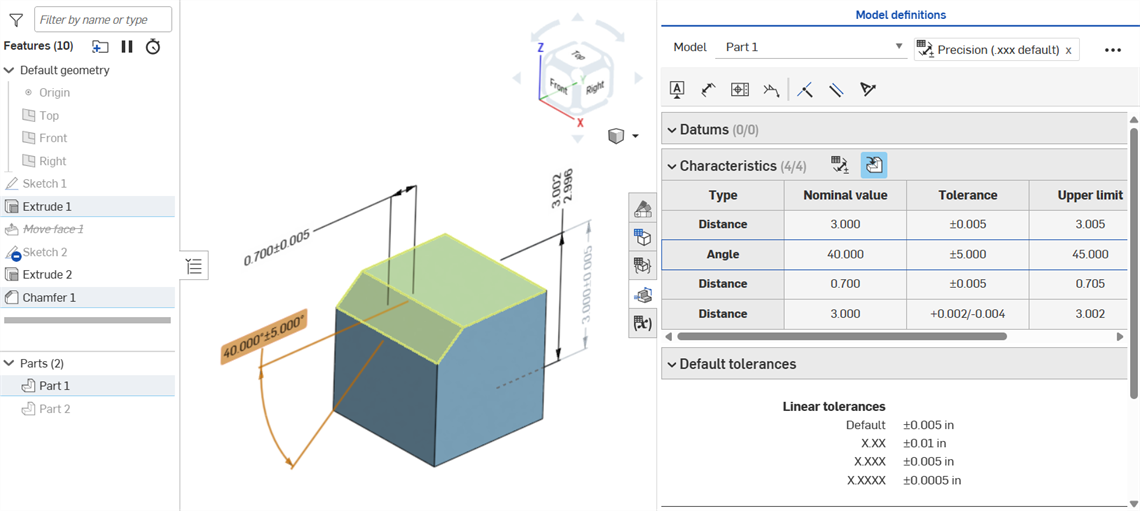

Hovering over value cells in the Characteristics table (for example, Nominal value, Tolerance, or Upper/Lower limit columns), cross-highlights the outline of the associated face(s) in the graphics area (in orange) and any associated driving dimensions or annotations, but not driven dimensions:

Hovering over the Nominal value cell cross-highlights the outline of the associated face in the graphics area, but not the associated driven dimension

Hovering over the Nominal value cell cross-highlights the outline of the associated face and driving dimension in the graphics area

-

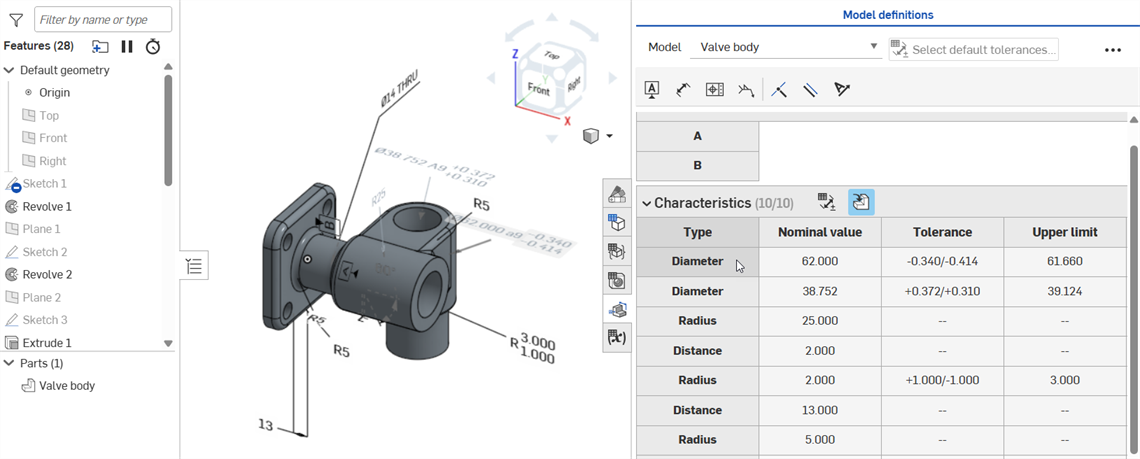

Clicking on a Datum or Type cell (for example, Distance, Diameter, or Radius) cross-highlights the associated face(s) in the graphics area (in yellow), the part in the Parts list, the associated dimension or annotation (whether driving or driven), and any associated feature in the Features list:

Clicking the Diameter cell cross-highlights the associated face in the graphics area, the part in the Parts list (Valve body), the driven dimension (Diameter) and feature in the Features list (Revolve 2)

-

Datum and Type cells are toggles. Clicking again deselects the cross-highlighting:

-

The following shows a chamfered edge. Clicking the Distance dimension in the graphics area cross-highlights one face if Equal distance is selected as the Chamfer type (left image), and two faces if Two distances is selected as the Chamfer type (middle image). Clicking the Angle dimension cross-highlights two faces if Distance and angle is selected as the Chamfer type (right image).

Highlighting when a dimension is selected in the graphics area: Equal distance (left), Two distances - when Distance 1 is selected (middle), Distance and angle - when Angle is selected (right)

Selecting a dimension in the graphics area (Angle in the example below) also places a blue border around the dimension in the Inspection table, and cross-highlights any associated feature in the Features list and part in the Parts list:

The cursor must be moved off the cell and then back over the cell again to display the cross-highlight after being deselected.

Each model's inspection table can be exported to an ordered CSV file, with a list of all the model's dimensions and annotations:

- Select the model from the Model dropdown:

- Click the overflow menu button (

) from the top right corner of the Inspection table.

) from the top right corner of the Inspection table. - Select Export to CSV:

-

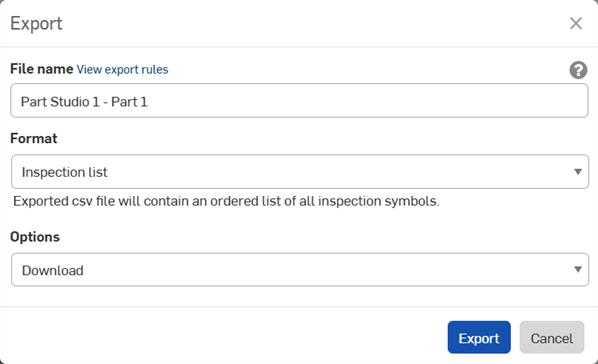

The Export dialog opens. Select from the following options:

-

File name - By default, the file name is the name of the Part Studio tab and model selected in Step 1. Optionally, overwrite this name with the file name you require.

-

Format - The output format. By default, Inspection list is selected. Keep this option selected.

- Options - Select one of the following options:

Download - Download the file to your computer.

Download and store file in a new tab - Download the file to your computer and also creates a new tab in the current Document where the file is stored.

Email with file download link - Email the exported file as a download link (that is, with all plan types except Free and Education). See Exporting via email with the file download link section below.

Store file in a new tab - Create a new tab in the current document where the file is stored.

The download location is browser-specific. If you'd like to be prompted to save to a different location, look in your browser settings for an option to ask where to save each file before downloading.

-

- If you downloaded the file to your computer, you can open it in a spreadsheet application such as Microsoft Excel (see image below), with annotation Type, Nominal value, Tolerance, Upper limit, and Lower limit columns:

Some spreadsheet applications automatically calculate or reformat symbols, including parentheses and positive and negative tolerance symbols. If your expected results are transmuted in the spreadsheet, you may have to reformat the data or use a text editor instead of a spreadsheet editor.

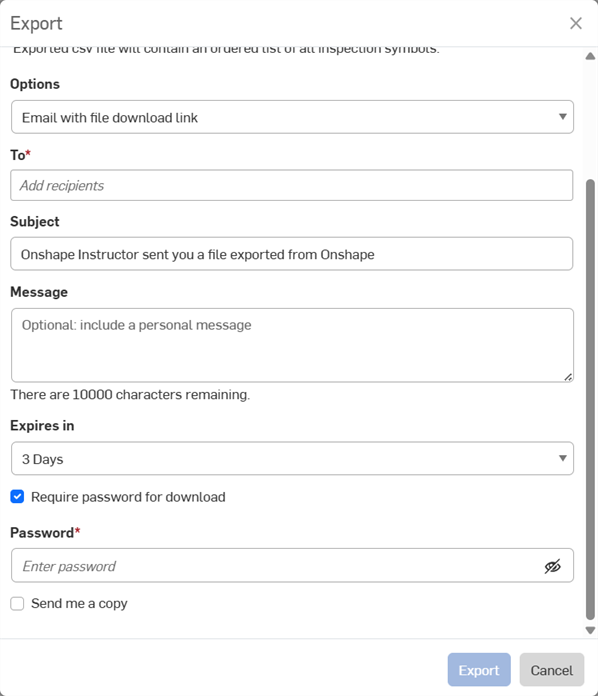

Exporting via email with file download link

With every export, you have the option to email the exported file as a download link (that is, with all plan types except Free or Education). When in the Export dialog:

-

Select Email with file download link under the Options dropdown:

-

Enter the following email options:

-

To - Recipients' email address (required).

-

Subject - A customized subject line for the email.

-

Message - An optional message.

-

Expires in - Specifies how long you want the download link to be available. The default is 3 days.

-

Require password for download - Check this option to password-protect the link you are emailing.

-

Password - With Require password for download checked, supply a password in this field. This is the password used to open the file sent via email.

-

Send me a copy - Sends a copy of the email to your (the author's) email.

-

Never email a password. A better practice is to specify in the message for the recipient to contact you for the password by other means.

The recipient receives an Onshape-branded email with the link to download the exported inspection table.