Sheet Metal Loft

Sheet Metal Loft

![]()

![]()

![]()

Create a sheet metal part that transitions between two profiles.

To create a sheet metal loft:

- While in a Part Studio, click the Sheet metal loft button (

).

).

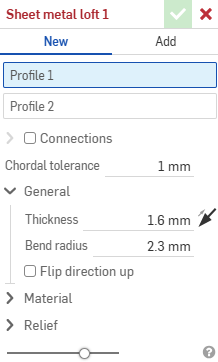

- Select New to create a new sheet metal part, or select Add to add the loft to an existing one.

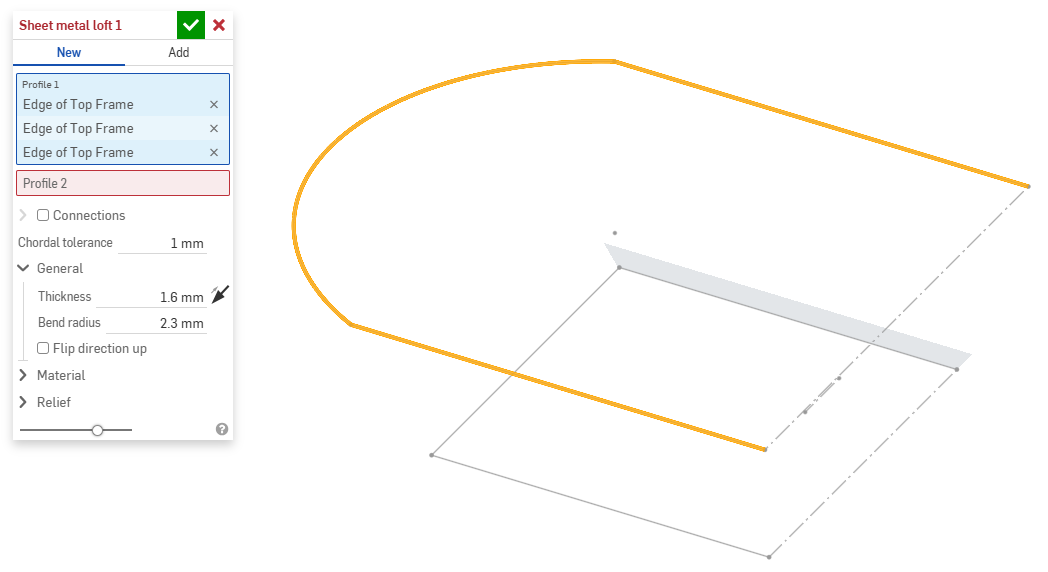

- With focus in the Profile 1 field, select the starting profile (region, face, edge, or point).

- With focus in the Profile 2 field, select the ending profile. Onshape creates a sheet metal model between the two profiles.

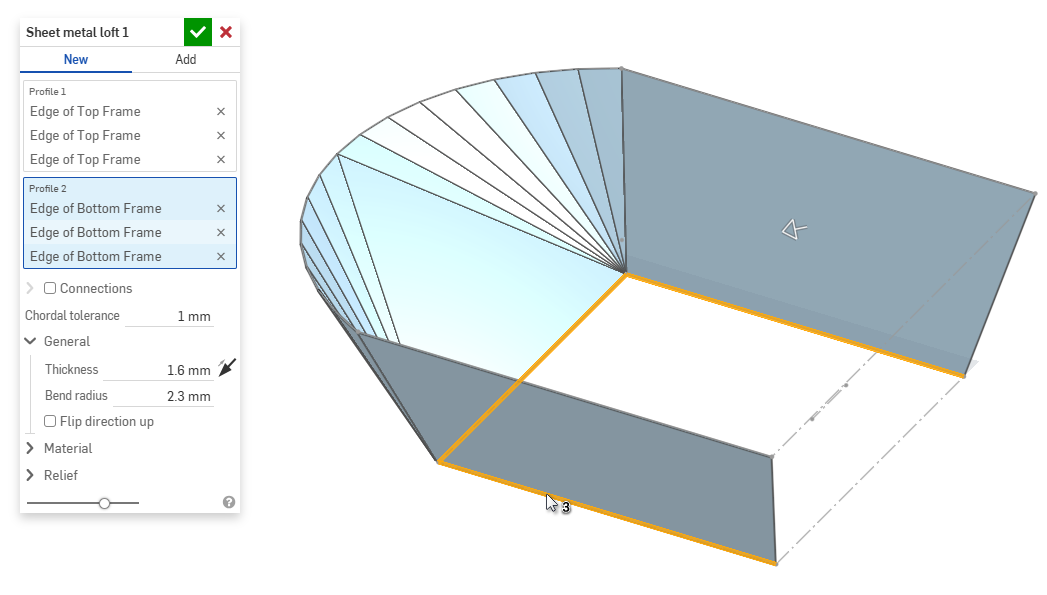

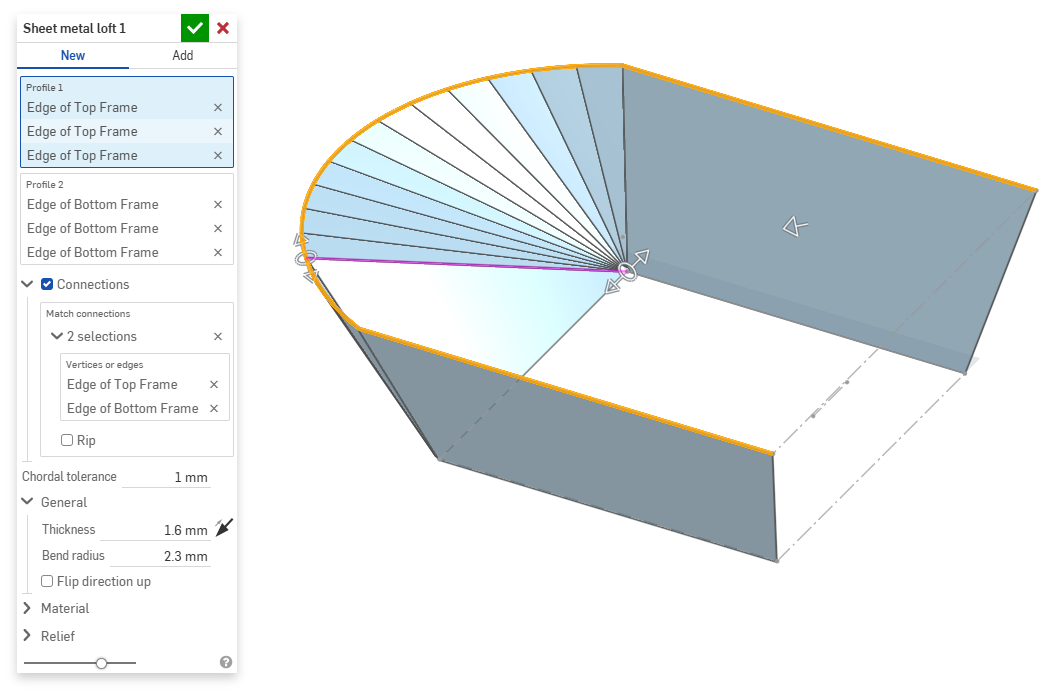

- Click the Connections checkbox for more control on the twist of the resulting model. Onshape estimates the proximity within the existing vertices/edges if no matches are specified.

- Select a vertex or edge from the loft and drag the manipulator(s) to adjust the connection.

- To divide the model into separate parts at the connection, select Rip.

- Select a vertex or edge from the loft and drag the manipulator(s) to adjust the connection.

- Use the Chordal tolerance field to set the maximum distance the tessellated geometry can vary from the underlying surface.

- When creating new sheet metal models, you can also expand the following sections to further refine the model:

- General:

- Thickness - Thickness of the sheet metal. Click the arrow to reverse the direction.

- Bend radius - Inside radius of the bends created.

- Flip direction up - Select to reverse the orientation of the sheet metal model and flat view. This is useful when defining whether bends are up or down relative to the model.

- Material (options in this section are identical to those provided in the Sheet metal model feature):

- 彎折計算 - 決定計算彎折的方式。選項有:

- K 係數 (預設) - 使用中立軸與材料厚度的比例。

- 彎折裕度 - 使用彎折相切點之間的中立線弧長。

- Bend deduction - Uses the difference between the sum of the flange lengths (from the edge to the apex) and the initial flat length.

會將在這裡選擇的彎折計算用為鈑金表格中的一個欄位。可以自訂每個彎折並可從表格中直接編輯。詳細資訊請參考鈑金表格與展開視圖。

- Default bend K Factor - The fraction of material thickness on which the neutral axis lies on a bend. (Default is 0.45.)

- Rolled K Factor - The fraction of material thickness on which the neutral axis lies on a section of rolled wall. (Default is 0.5.)

- 彎折計算 - 決定計算彎折的方式。選項有:

- Relief (options in this section are identical to those provided in the Sheet metal model feature):

- Minimal gap - The smallest gap between the sheet metal edges defining a rip.

- Corner relief type -

- 正方形 - 尺寸

展開視圖:

3D 視圖:

3D 視圖:

- 矩形 - 縮放

展開視圖:

3D 視圖:

3D 視圖:

- 圓形 - 尺寸

展開視圖:

3D 視圖:

3D 視圖:

- 圓形 - 縮放

展開視圖:

3D 視圖:

3D 視圖:

- 封閉

展開視圖:

3D 視圖:

3D 視圖:

- 簡易

展開視圖:

3D 視圖:

3D 視圖:

- 正方形 - 尺寸

- Corner relief scale - The scale of the corner opening (for Scaled openings), a value between 1.00 and 2.00.

- Bend relief type - The shape of the bend relief:

- Rectangle - Scaled

- 圓端 - 縮放

- 撕裂

- Rectangle - Scaled

- Bend relief depth scale - A value between 1.00 and 5.00. Once you enter a value it becomes the default across all documents.

- A value of 1 results in an obround bend relief perfectly touching the bend and a rectangular bend relief matches the depth of the obround.

- Any value past 1 adds depth via the formula:

(depth scale -1) * bendRadius

- Bend relief width scale - A value between 0.0625 and 2.00. Once you enter a value, it becomes the default across all documents. The width of the bend relief is calculated via the formula:

thickness * width scale。

- General:

- When adding to an existing sheet metal model, click the Merge scope field, then select the part to add to. The merge scope can only accept bodies of a single active sheet metal model.

當鈑金模型啟用時 (在建立或編輯鈑金的過程中),其他可用的工具包括:

-

凸緣 - 為每條所選的邊線建立牆面,使用彎折來連接所選的邊線。

凸緣 - 為每條所選的邊線建立牆面,使用彎折來連接所選的邊線。 -

摺邊 - 在現有的鈑金零件上為所選取的邊線/面建立摺邊。

摺邊 - 在現有的鈑金零件上為所選取的邊線/面建立摺邊。 -

薄板頁 - 將一個薄板頁加入至鈑金凸緣中。

薄板頁 - 將一個薄板頁加入至鈑金凸緣中。 -

Bend - Bend a sheet metal model along a reference line, with additional bend control options.

Bend - Bend a sheet metal model along a reference line, with additional bend control options. -

Form - Create form features on existing sheet metal models. Forms can be selected from the current document, other documents, or a predefined library of sheet metal forms.

Form - Create form features on existing sheet metal models. Forms can be selected from the current document, other documents, or a predefined library of sheet metal forms. -

Loft - Create sheet metal models that connect two profiles.

Loft - Create sheet metal models that connect two profiles. -

製作接合 - 將兩個牆面的相交處轉換為一個接合特徵,可以是一個彎折 (以圓柱幾何接合牆面),或是一個裂口 (兩個牆之間的小間隙)。

製作接合 - 將兩個牆面的相交處轉換為一個接合特徵,可以是一個彎折 (以圓柱幾何接合牆面),或是一個裂口 (兩個牆之間的小間隙)。 -

轉角 - 修改轉角類型與止裂比例。

轉角 - 修改轉角類型與止裂比例。 -

彎折止裂 - 修改彎折止裂 (在彎折結束與自由邊線交會處做出的小切除)、深度與止裂寬度。

彎折止裂 - 修改彎折止裂 (在彎折結束與自由邊線交會處做出的小切除)、深度與止裂寬度。 -

Modify joint - Make changes to an existing joint, such as converting a bend to a rip. Currently available through the flat view table.

Modify joint - Make changes to an existing joint, such as converting a bend to a rip. Currently available through the flat view table. -

尖角倒鈍 - 套用圓角或倒角來在現有的鈑金零件上鈍化尖角。選擇尖角邊線或頂點,然後指定尖角倒鈍類型與距離。建議在完成鈑金模型的所有凸緣與接合後再使用這個特徵。

尖角倒鈍 - 套用圓角或倒角來在現有的鈑金零件上鈍化尖角。選擇尖角邊線或頂點,然後指定尖角倒鈍類型與距離。建議在完成鈑金模型的所有凸緣與接合後再使用這個特徵。 -

Sheet metal table and flat view - Open and close the Rip/Bend tables and the visualization of the sheet metal model flat pattern. Use this table to convert rips to bends and vice versa.

Sheet metal table and flat view - Open and close the Rip/Bend tables and the visualization of the sheet metal model flat pattern. Use this table to convert rips to bends and vice versa. -

完成鈑金模型 - 關閉 (停用) 鈑金模型;建立特徵清單中的特徵。

完成鈑金模型 - 關閉 (停用) 鈑金模型;建立特徵清單中的特徵。

iOS and Android support for the sheet metal loft feature is limited to viewing and editing lofts created from the desktop (browser) platform.

當鈑金模型啟用時 (在建立或編輯鈑金的過程中),其他可用的工具包括:

-

凸緣 - 為每條所選的邊線建立牆面,使用彎折來連接所選的邊線。

凸緣 - 為每條所選的邊線建立牆面,使用彎折來連接所選的邊線。 -

薄板頁 - 將一個薄板頁加入至鈑金凸緣中。

薄板頁 - 將一個薄板頁加入至鈑金凸緣中。 -

製作接合 - 將兩個牆面的相交處轉換為一個接合特徵,可以是一個彎折 (以圓柱幾何接合牆面),或是一個裂口 (兩個牆之間的小間隙)。

製作接合 - 將兩個牆面的相交處轉換為一個接合特徵,可以是一個彎折 (以圓柱幾何接合牆面),或是一個裂口 (兩個牆之間的小間隙)。 -

轉角 - 修改轉角類型與止裂比例。

轉角 - 修改轉角類型與止裂比例。 -

彎折止裂 - 修改彎折止裂 (在彎折結束與自由邊線交會處做出的小切除)、深度與止裂寬度。

彎折止裂 - 修改彎折止裂 (在彎折結束與自由邊線交會處做出的小切除)、深度與止裂寬度。 -

Loft - View and modify sheet metal models that connect two profiles.

Loft - View and modify sheet metal models that connect two profiles. -

尖角倒鈍 - 套用圓角或倒角來在現有的鈑金零件上鈍化尖角。選擇尖角邊線或頂點,然後指定尖角倒鈍類型與距離。建議在完成鈑金模型的所有凸緣與接合後再使用這個特徵。

尖角倒鈍 - 套用圓角或倒角來在現有的鈑金零件上鈍化尖角。選擇尖角邊線或頂點,然後指定尖角倒鈍類型與距離。建議在完成鈑金模型的所有凸緣與接合後再使用這個特徵。 -

完成鈑金模型 - 關閉 (停用) 鈑金模型;建立特徵清單中的特徵。

完成鈑金模型 - 關閉 (停用) 鈑金模型;建立特徵清單中的特徵。